The vehicle system referenced provides electronic stability and traction control. When a malfunction is detected within this system, a notification alerts the driver. This notification could manifest as a warning light on the instrument panel, accompanied by a message in the driver information center. This signals that the electronic stability and traction control functionalities may be impaired.

The correct functioning of this system is vital for maintaining vehicle control, particularly in challenging driving conditions. Historically, these systems have evolved significantly, progressing from basic traction control to sophisticated stability programs that integrate multiple sensors and actuators. Their implementation has led to a demonstrable reduction in accidents and improved vehicle safety ratings across various models. Furthermore, understanding the operational status of this system allows for informed decisions regarding vehicle operation and maintenance.

The following sections will elaborate on troubleshooting procedures, potential causes for system alerts, and necessary maintenance steps to ensure its proper operation. Additionally, information on diagnostic tools and repair strategies for this critical vehicle component will be provided.

1. System Malfunction

A “System Malfunction” pertaining to the vehicle stability control is a critical issue that triggers a notification, often indicated by the phrase “service advancetrac.” This alert signifies a potential compromise in the vehicle’s ability to maintain optimal traction and stability, potentially impacting safety and handling.

-

Sensor Failure

Defective wheel speed sensors, yaw rate sensors, or steering angle sensors are common causes of system malfunctions. These sensors provide crucial data for the stability control system to function correctly. For example, a faulty wheel speed sensor might report inaccurate data, leading the system to incorrectly engage braking or throttle intervention, thus triggering the alert. Diagnostic testing is required to identify a specific sensor failure.

-

Hydraulic Control Unit (HCU) Issues

The HCU, which manages brake pressure to individual wheels, can malfunction due to internal failures or electrical issues. A failure within the HCU can prevent the system from applying brakes as needed during a skid or loss of traction, resulting in compromised stability and illumination of the “service advancetrac” message. This may require replacement or recalibration of the HCU.

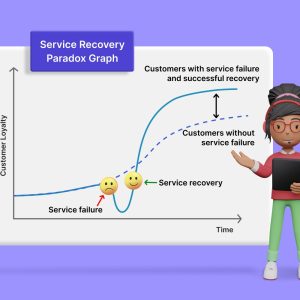

Suggested read: Unity Service Recovery: Restoring Operations and Customer Trust After Service Failures

-

Software Glitches

Modern vehicle systems rely on complex software. Errors in the software controlling the stability system can lead to false alarms or incorrect system behavior. Software glitches can arise from corrupted data, incomplete updates, or conflicts with other electronic modules. A software reflash or update may be necessary to resolve these issues.

-

Wiring and Connector Problems

Damage to wiring harnesses or corroded connectors can disrupt the communication between sensors, the HCU, and the vehicle’s central control unit. Intermittent connection problems can trigger the “service advancetrac” notification even if the system components themselves are functioning correctly. Inspection and repair of wiring and connectors are critical to eliminating this source of malfunction.

Addressing a “System Malfunction” associated with the warning is vital for restoring the vehicles intended safety characteristics. Prompt diagnosis and repair, encompassing sensor checks, HCU evaluation, software updates, and wiring inspections, are essential to ensure the system operates correctly and prevent potential safety hazards. Ignoring the warning could compromise vehicle handling, especially in adverse conditions.

2. Warning Indicator

The illumination of a “Warning Indicator” related to the “service advancetrac” system signifies a detected anomaly within the vehicle’s electronic stability control (ESC) or traction control system (TCS). This indicator serves as a primary means of alerting the driver to a potential reduction in vehicle stability or traction. The underlying cause may range from a temporary sensor glitch to a more serious component failure. For example, if a wheel speed sensor provides inconsistent readings, the system may register a fault, activating the warning indicator to prompt driver awareness and potential investigation. The indicator is a crucial component for highlighting compromised systems, enabling drivers to make informed decisions and seek appropriate maintenance.

Real-world examples underscore the practical significance of understanding this connection. In scenarios involving icy or wet road conditions, the “service advancetrac” system is designed to intervene by modulating brake pressure and engine torque to maintain vehicle control. However, if the warning indicator is illuminated, this intervention might be compromised, potentially leading to loss of control. Thus, recognizing the warning and understanding its implications allows drivers to adjust their driving style accordingly, mitigating risk. Furthermore, diagnosing the cause of the indicator illumination necessitates professional-grade diagnostic tools to isolate the faulty component or condition, facilitating effective repairs.

In summary, the relationship between the “Warning Indicator” and “service advancetrac” is one of cause and effect, where the indicator’s activation reflects an underlying system fault. Understanding this connection is vital for promoting driver safety and ensuring the proper functioning of the vehicle’s stability control mechanisms. Ignoring the indicator may increase the risk of accidents, particularly in adverse driving conditions. Consequently, a prompt and thorough diagnosis of the indicator’s cause is essential for maintaining vehicle safety.

3. Electronic Stability

Electronic Stability is a crucial vehicle safety system designed to mitigate loss of control situations. When the “service advancetrac” system experiences a fault, the functionality of Electronic Stability is often directly affected, potentially diminishing its ability to assist the driver in maintaining directional control.

-

Yaw Rate Correction

Electronic Stability systems utilize yaw rate sensors to detect when a vehicle begins to rotate excessively, indicating a potential skid. If the “service advancetrac” system malfunctions, the ability to accurately measure and correct yaw may be compromised. For example, in a sudden swerve to avoid an obstacle, the Electronic Stability system may be unable to apply brakes individually to counteract the rotation, increasing the risk of a spin. This is particularly relevant in high-speed maneuvers or on slippery surfaces.

-

Traction Enhancement

Electronic Stability systems often incorporate traction control, which prevents wheelspin during acceleration. A malfunctioning “service advancetrac” system can disrupt this function, leading to excessive wheelspin and reduced acceleration, especially on low-friction surfaces. Consider a situation where a vehicle is accelerating on ice; a properly functioning Electronic Stability system would limit wheelspin, optimizing traction. However, with a “service advancetrac” alert, this may not occur, potentially leading to a loss of forward momentum and control.

-

Roll Stability Control

Some vehicles equipped with Electronic Stability also have Roll Stability Control, which aims to prevent rollovers. This system uses sensors to detect when a vehicle is at risk of tipping. If “service advancetrac” is triggered, the Roll Stability Control might not activate correctly, potentially increasing the likelihood of a rollover in extreme situations, such as during abrupt lane changes or off-road driving.

-

Brake Distribution

Electronic Stability systems actively manage brake force distribution among individual wheels. A “service advancetrac” alert suggests that this precise brake modulation might be impaired. For example, during emergency braking, the system might be unable to optimally distribute brake force to maintain stability, possibly resulting in wheel lockup and reduced stopping distance. Therefore, the interplay between Electronic Stability and precise brake management is vital for safe vehicle operation.

Therefore, maintaining the functional integrity of Electronic Stability and promptly addressing alerts associated with “service advancetrac” is paramount. The interdependency between these systems means that any compromise in one directly affects the overall safety and control characteristics of the vehicle. Understanding these connections is crucial for informed driving and timely maintenance.

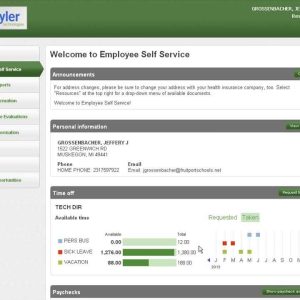

Suggested read: Munis Self Service: Your Complete Resource for Employee and Citizen Portal Access

4. Traction Control

Traction Control, an integral component of modern vehicle safety systems, works to prevent wheel slippage, optimizing grip and stability, especially during acceleration. When the “service advancetrac” system indicates a problem, Traction Control functionality can be directly compromised, potentially affecting vehicle handling and safety.

-

Wheel Speed Monitoring

Traction Control relies on wheel speed sensors to detect disparities in rotational velocity among the wheels. If one or more wheels spin excessively, the system intervenes to reduce engine power or apply braking force to those wheels. A “service advancetrac” alert may indicate a fault in these sensors or the control module, leading to ineffective or absent Traction Control. For example, attempting to accelerate on a slick surface with a malfunctioning system could result in uncontrolled wheelspin and reduced vehicle stability.

-

Engine Torque Management

A key function of Traction Control is to limit engine torque output when wheel slippage is detected. This reduction in torque prevents the wheels from spinning freely, maximizing available traction. However, if the “service advancetrac” system is triggered, the engine torque management aspect of Traction Control may not function correctly, resulting in an inability to control wheelspin and potentially hazardous driving conditions. The system’s effectiveness in regulating torque becomes questionable.

-

Brake Application

In addition to managing engine torque, Traction Control can apply individual brakes to spinning wheels. This selective braking action redirects power to wheels with better grip, improving overall traction. If the “service advancetrac” system reports an issue, the brake application component of Traction Control may become impaired, leading to compromised traction in situations where individual wheels lose grip. The appropriate and timely braking is essential for stability.

-

System Integration

Traction Control is often integrated with other vehicle systems, such as anti-lock braking (ABS) and Electronic Stability Control (ESC). A “service advancetrac” message may signify broader system integration problems, impacting the coordinated functioning of these safety systems. Consequently, the vehicle’s ability to respond effectively to dynamic driving situations could be reduced, necessitating prompt diagnostic evaluation.

In conclusion, the effective operation of Traction Control is directly linked to the overall health of the “service advancetrac” system. A malfunction within this system compromises Traction Control’s functionality, potentially affecting vehicle stability and safety, particularly in adverse driving conditions. The proper wheel spin is imperative to ensure that the vehicle does not pose danger to the public.

5. Diagnostic Codes

Diagnostic Codes serve as a critical link in identifying the root cause of “service advancetrac” alerts. These codes, generated by the vehicle’s onboard computer, provide technicians with specific information regarding the nature and location of system faults, allowing for targeted and efficient repairs. The presence of a “service advancetrac” notification almost always corresponds to one or more stored diagnostic codes, which are accessed through specialized diagnostic tools.

-

Code Identification

Diagnostic codes are typically alphanumeric, following standardized formats (e.g., P0XXX, C0XXX, B0XXX, U0XXX). Each character provides specific information. For instance, the first character indicates the system affected (P=Powertrain, C=Chassis, B=Body, U=Network). The subsequent digits narrow down the fault to a specific component or circuit. Example: Code C1234 might indicate a fault in the right front wheel speed sensor circuit, directly relevant to the “service advancetrac” system if that sensor is providing erroneous data. Understanding this code structure is essential for accurately interpreting the diagnostic information.

-

Fault Localization

Diagnostic codes assist in pinpointing the faulty component or circuit within the complex “service advancetrac” system. For example, a code related to the yaw rate sensor would direct the technician to examine that specific sensor and its associated wiring. Without diagnostic codes, troubleshooting would involve a time-consuming and less accurate process of elimination. The codes streamline the diagnostic process, saving time and reducing the potential for misdiagnosis.

-

Troubleshooting Guidance

Diagnostic codes often come with suggested troubleshooting steps and potential repair procedures. Automotive repair databases and diagnostic software provide detailed information associated with each code, outlining common causes, testing methods, and recommended repairs. For instance, if a code indicates a faulty steering angle sensor, the troubleshooting guidance might include steps to check sensor calibration, wiring integrity, and sensor resistance, ultimately leading to a definitive repair strategy. Thus, diagnostic codes not only identify the problem but also guide the repair process.

-

Intermittent Faults

Suggested read: Managed Equipment Services: Transform Your Business Operations with Strategic Asset Management

Diagnostic codes can also help identify intermittent faults, which are notoriously difficult to diagnose. These faults may not be present at all times, but the onboard computer stores a code when the fault occurs. While the “service advancetrac” light might not be constantly illuminated, the presence of a stored code can provide valuable insight into the nature and frequency of the intermittent problem. This allows technicians to take proactive measures to address the underlying cause before it becomes a persistent issue.

In summary, Diagnostic Codes are indispensable for accurately diagnosing issues related to “service advancetrac”. They provide specific information about the nature and location of system faults, guide troubleshooting efforts, and assist in resolving both persistent and intermittent problems. Their proper interpretation is essential for efficient and effective repairs, ensuring the restored functionality of the vehicle’s stability control systems.

6. Sensor Calibration

Sensor Calibration is a crucial process in ensuring the accurate operation of vehicle stability systems. Improper calibration directly impacts the functionality of systems that trigger the “service advancetrac” alert, affecting vehicle handling and safety. The precision of these sensors is fundamental to the vehicle’s ability to maintain stability in various driving conditions.

-

Steering Angle Sensor Calibration

The steering angle sensor measures the driver’s steering input, a critical data point for stability control. Miscalibration leads to the system misinterpreting steering commands, causing inappropriate or absent system intervention. For instance, the system may incorrectly apply brakes during normal cornering, or fail to intervene during a skid. Proper calibration aligns the sensor output with the actual steering angle, preventing erroneous activation of “service advancetrac” and maintaining accurate stability control. Real-world consequences include unpredictable vehicle behavior and reduced driver confidence.

-

Yaw Rate Sensor Calibration

The yaw rate sensor measures the vehicle’s rotational velocity, indicating its tendency to spin or drift. Incorrect calibration leads to the system misjudging the vehicle’s rotation, impairing its ability to correct skids. A miscalibrated sensor might signal excessive rotation when the vehicle is stable, or fail to detect a developing skid. Correct calibration ensures accurate yaw rate measurements, enabling effective skid correction and minimizing the risk of “service advancetrac” activation. Examples involve compromised vehicle control during emergency maneuvers.

-

Accelerometer Calibration

Accelerometers measure the vehicle’s acceleration in various directions, providing information about its movement and stability. Incorrect calibration leads to the system misinterpreting the vehicle’s dynamics, negatively affecting its ability to respond to changes in direction or speed. A miscalibrated accelerometer might trigger stability control unnecessarily or fail to engage during critical moments, contributing to the “service advancetrac” alert. Proper calibration ensures that the system accurately detects and responds to changes in the vehicle’s motion, enhancing overall stability and safety.

-

Wheel Speed Sensor Synchronization

While not calibration in the strictest sense, wheel speed sensor synchronization is crucial. Discrepancies between wheel speed sensor readings, even without individual sensor malfunction, can trigger the “service advancetrac” system. These discrepancies can arise from tire wear differences or slight variations in sensor mounting. The system interprets these differences as potential wheel slippage, leading to unnecessary interventions or a general system fault. Ensuring synchronized wheel speed signals is essential for preventing false alarms and maintaining smooth, predictable system operation. This contributes directly to preventing activation of the “service advancetrac” notification.

These calibration procedures are essential components to ensure the “service advancetrac” system functions as intended. Neglecting proper calibration or synchronization can lead to unpredictable vehicle behavior and potentially compromise driver safety. Therefore, these procedures are important for diagnostic protocols. It is advised to seek a professional for troubleshooting sensor issues.

Frequently Asked Questions About Service Advancetrac

The following questions and answers address common concerns regarding the system notification, providing clarity on its meaning and implications.

Question 1: What does a “Service Advancetrac” message indicate?

A “Service Advancetrac” message signifies a detected malfunction within the vehicle’s electronic stability control (ESC) system, including traction control functionality. This may involve sensor errors, hydraulic control unit issues, or software anomalies that compromise the system’s ability to maintain vehicle stability and traction.

Question 2: Is it safe to drive with a “Service Advancetrac” warning illuminated?

Suggested read: Chain Link Services: Everything You Need to Know About Professional Chain Link Fencing Solutions

While the vehicle remains drivable, operating it with an active “Service Advancetrac” warning is not recommended. The impaired ESC system may not function correctly in situations requiring stability intervention, increasing the risk of accidents, particularly on slippery surfaces or during emergency maneuvers. Reduced handling is to be anticipated.

Question 3: What are the common causes of a “Service Advancetrac” alert?

Common causes include faulty wheel speed sensors, yaw rate sensor malfunctions, steering angle sensor issues, hydraulic control unit problems, and software glitches. Damaged wiring or corroded connectors in the system can also trigger this warning. A diagnostic scan is required to pinpoint the precise origin of the alert.

Question 4: How is the “Service Advancetrac” system diagnosed and repaired?

Diagnosis involves using specialized diagnostic scan tools to retrieve fault codes stored in the vehicle’s computer. Repair may involve replacing faulty sensors, repairing wiring issues, recalibrating sensors, or, in some cases, replacing the hydraulic control unit or reflashing the system software. All work should be preformed by a professional.

Question 5: Can the “Service Advancetrac” system be reset, and if so, how?

Resetting the system without addressing the underlying cause is not advisable and will likely result in the warning returning. While clearing the fault codes can temporarily extinguish the warning light, the issue will persist until properly diagnosed and repaired. The underlying causes must be repaired.

Question 6: Will driving with a “Service Advancetrac” issue cause further damage to the vehicle?

Potentially, yes. In addition to the immediate risk of reduced stability control, prolonged driving with an unresolved issue could place additional strain on other related systems, potentially leading to further component failures. Addressing the issue promptly minimizes the risk of secondary damage. There can be a cascade of issues from neglecting the problem.

In conclusion, understanding the “Service Advancetrac” system and addressing any associated warnings promptly are essential for maintaining vehicle safety and performance. Addressing the message should be a priority.

The following section will provide a comprehensive analysis of the long-term implications of neglecting a “Service Advancetrac” warning and its overall impact on vehicle reliability.

Guidance Regarding “Service Advancetrac” Notifications

The following guidelines offer practical advice for handling notifications, emphasizing proactive maintenance and informed decision-making to ensure vehicle safety and operational integrity.

Tip 1: Immediate Assessment Upon Notification Notification activation warrants immediate assessment. Note driving conditions and any unusual vehicle behavior preceding the alert. This preliminary information aids in subsequent diagnosis.

Tip 2: Diagnostic Code Retrieval Retrieve diagnostic codes using an appropriate scan tool. These codes offer insights into the source of the malfunction and guide targeted troubleshooting. Consult a qualified technician if code interpretation proves challenging.

Suggested read: Integrated Service Solutions: Transforming Business Operations Through Unified Management

Tip 3: Sensor Inspection and Testing If diagnostic codes point to specific sensors (e.g., wheel speed, yaw rate, steering angle), thoroughly inspect these sensors and their associated wiring for damage or corrosion. Use a multimeter to verify sensor functionality according to manufacturer specifications.

Tip 4: Hydraulic Control Unit Evaluation If sensor checks prove inconclusive, evaluate the hydraulic control unit (HCU) for proper operation. Confirm that the HCU is receiving power and ground signals. Consider consulting a specialist for HCU diagnosis and repair, as this component is complex.

Tip 5: Software Update Verification Ensure that the vehicle’s electronic control modules have the latest software updates. Outdated software can cause communication errors and trigger false “Service Advancetrac” notifications. Consult a dealership or qualified repair facility for software updates.

Tip 6: Tire Condition Uniformity Verify that all tires are of the same size, type, and have comparable tread depth. Uneven tire wear can cause discrepancies in wheel speed readings, triggering system alerts. Replace tires as needed to maintain uniformity.

Tip 7: Professional Consultation When uncertain, consult a qualified automotive technician specializing in electronic stability control systems. Attempting complex repairs without proper knowledge and tools can exacerbate the problem and compromise vehicle safety.

Adherence to these guidelines will facilitate effective management of “Service Advancetrac” notifications, minimizing potential risks and ensuring the continued safe operation of the vehicle.

The concluding section summarizes the significance of understanding the “Service Advancetrac” system and emphasizes the importance of proactive maintenance for long-term vehicle reliability.

Concluding Remarks on Service Advancetrac

The preceding analysis has explored various facets of the “service advancetrac” system, emphasizing its critical role in maintaining vehicle stability and driver safety. From diagnostic codes and sensor calibration to troubleshooting procedures and preventative maintenance, the discussion underscores the intricate nature of this electronic stability control system and its direct impact on vehicle handling characteristics. Ignoring system alerts can lead to compromised safety and potential component failures, demanding a comprehensive understanding of system functions and proactive maintenance practices.

Therefore, recognizing the significance of “service advancetrac” and its associated warnings, it is imperative to prioritize proactive inspection and maintenance. Vigilant monitoring of the system’s operational status and prompt attention to any detected anomalies are essential for preserving vehicle safety and ensuring optimal performance. Neglecting these measures may result in increased risks and diminished vehicle reliability, underscoring the necessity for informed decision-making and responsible vehicle ownership. Future advancements in diagnostic technology may further enhance the precision and efficiency of “service advancetrac” system maintenance, reinforcing the importance of staying informed and prepared to address potential system malfunctions.