How to Repair Rust on Your Car Without Welding. I’m going to show you how to remove and repair rust damage on your vehicle. Now, unfortunately, it’s common to get rust around the lower portions of the car, as well as around the wheel wells. What happens is while you drive the car, a rock, kicks up and chips, the paint exposing raw metal over time that raw metal rusts, and then you get this disaster right here.

So, in order to avoid large rust damage like this or rust, damage like that, it’s important that when you find a small piece of rust or a little paint bubble like that, that you fix it right away, so it doesn’t spread into something much worse, and here Is what I mean? This is my 1995 ford windstar, which my family has owned since brand new.

It has over three hundred thousand miles and you could tell because it has a couple of rust spots like this right here, which is repairable, and this down here, which is not this type of rust damage. Is the perfect example of why you don’t want rust to spread this rust is so bad. I could break this right off with my hands and the panel is so weak.

It just crumbles rust damage. This bad can’t be repaired has to be replaced, so you’re going to have to weld in your own custom sheet metal right here and that’s why it’s important to repair rust as soon as you see it. So let me show you how to repair rust damage just like this we’re going to go from this to this, and that is a huge improvement.

We’re going to stop the spreading of the rust and make it look a lot better. The best part is, you could do this at home yourself inexpensively using these products, so here’s everything that you’re going to need and although it seems like a lot, it’s really not that bad. You have your sandpaper, your body filler and your spray paint and, most importantly, you have your eye protection gloves and your dust mask, and I want to thank 3m for supporting the video and sending me out all these products.

So I could show you guys how to repair rust damage so, instead of going to a body shop and spending hundreds, maybe even thousands of dollars, repairing rust you’ll be able to do it yourself.

So let me show you how rust repair takes four simple steps. First, remove all the rust with sandpaper next you’re going to fill the area with body filler. Then you’re going to stand that filler smooth with the body of your car and finally to prevent rust in the future finish the job by painting it now we’re going to be working on this large rust area right here.

Suggested read: Kyrio Home Services: Your Complete Resource for Professional Home Solutions

This is about as bad as it gets before. You have to actually cut it out, weld in your own sheetmetal, and the first thing we need to do is remove all the rust and bubbled up paint. So we have a bare metal surface to work on, but before we do that, we want to grab our rubbing alcohol or an adhesive remover spray spray down the area, and this removes any wax dirt or oils. So when we sand this down, we won’t contaminate the metal underneath and one more thing we need to do before we start sanding.

Since this is plastic, it doesn’t rust. So let’s get it out of the way, so we don’t sand it by mistake. This is still good paint, so this just pops out and we’ll move this down like that. So it’s out of the way all right now we could grab our sandpaper and send all this away.

We’re going to start out with our 80 grit and for those of you who don’t know the smaller, the grit number, the more aggressive and the more gritty the sandpaper is so 40 grit sandpaper is even more aggressive. A thousand grit sandpaper is very fine, so we’re starting with something that’s pretty aggressive, so that we could remove all the rust – and I like using a sanding block with my sandpaper, which allows me to apply pressure evenly since we’re sanding.

Be sure to have your dust mask on and the goal here is to remove all the rust by sanding it down to the bare metal surface, even if you leave just a little bit of rust after your repair is done. It’s just going to spread again, and you did all that work for nothing.

Also, the body filler needs the bare metal to it here properly, so take your time and be sure to remove every speck of rust all the way down to the bare metal – and this is looking awesome now you can see part of the technique. Is you want to send past the rust you don’t want to just stand on top of the rust you want to go on to this clean sheet metal about an inch that way. You know for sure that you got all the rust out around the damaged areas. At the same time, you don’t want to sand too far up, because you want to keep your repair area as small as possible.

The next thing I want to note are these holes that we created, because the rust was so bad here that it ate through the sheet metal, but don’t worry, we can easily patch these holes with adhesive body patch. This stuff is like chicken wire which will go behind the hole and then, when we add our glass filler, which is a fiberglass stranded filler, not only will it fill these holes, but it’s actually going to strengthen it to make it just as stronger, if not even Stronger than before,

so when we’re done, you won’t even know, there’s a hole there and it’ll look great now going back to sanding real quick, I’m going to be using sandpaper and hand sanding this entire video, because that’s something everyone could do. But if you do have a drill or an angle grinder, they do make attachments.

Here’s a drill, attachment that helps rust. Here’s a drill attachment that helps sends you can add different sanding grits on to this, or you could use a flat disk on your angle, grinder or a metal wire brush on your angle. Grinder and all these products will help you do these repairs a lot quicker, but they’re not necessary.

All you need is some sandpaper to get the job done now, after all, that sanding and rust removal, this sheet metal that had to rust on it, is going to. Be thinner and weaker than the good sheet metal above it. So what we need to do is use a fiberglass strand filler, which is going to give strength to this and also fill in all the little holes. But in order to do that, we’re going to be adding it on top of here and if we add it right now, it’s going to create a hump and we want this to be flush, so grab a hammer and hammer the damage sheet metal inwards.

So we’re basically denting the sheet metal so that the fiberglass filler could fill this area and strengthen our panel. Now, if you’re not working on a large area like this and you just have a little small rough spot, you can grab a screwdriver and then hammer the screwdriver inwards into that little rough spot. You don’t need to use a large hammer and create an even bigger dent and fill even larger and that’s a helpful trick if you’re working on little rough spots.

So with our body panel prepped, we are done with the front of the panel, but one thing most people forget if there’s rust on the front odds, are there’s rust on the back. So, let’s safely jack up, the car put it on jack stands and remove the wheel. So we could get to all the rust behind this panel and, as you can see, there’s a good amount of rust that we need to remove so grab your 80 grit sandpaper and start standing away and just like we did in the front back here.

We want to remove all the rust and get down to bare sheet metal. Just like this good and once you finish, sanding clean the area, so we could get it ready for paint. So this is going to be a twostep paint process. First, we’re going to use the rust reformer.

This paint will not only coat the bare metal, but if we happen to miss any rust it chemically bonds to that rust and converts it into a paintable surface. And if you can’t tell it’s definitely a challenge to spray backwards behind the quarter panel, but there we go. It looks like I covered everything now, after our paint’s dry, we’re going to go and do the undercoating. The undercoating is a rubberized coating that goes on thick.

There’s not only seal in the good metal, but it’s rubberized, so it won’t chip like regular paint when rocks kick up, and this is actually not a idea to do to prevent rust, even if your car than have any so make sure you coat the entire wheel. Well and let it dry all right now check it out, this came out great and the whole wheel well is protected, so removing the rust and under coating. The back of the panel is a very important step so that the rust doesn’t bleed through and eat.

Suggested read: Schools Advisory Service Login: Your Complete Access Guide to Educational Support Platforms

The panel up again a lot of people, don’t do that and then you end up with the same rust issues with that done. We could get the wheel back on and lower the car to the ground, all right. So before moving on to the next step, we have one more thing we need to do, and that is using the body patch to fill behind the holes and also rebuild this bottom corner here.

This body patch is a stainless steel mesh and what we need to do is we need to size it up for the area that we need to fix, so just put it in here and bend it to size, and then you can just use a regular household Scissors to cut it to size and we’re going to put this behind the body panel, not on top, if we put it on top we’re not going to be able to sand it down smooth with the body panel, but one place behind it.

It’ll support the filler and reinforce the sheet metal. Now we could fit the bumper, so we have an idea of where the patch needs to bend beautiful. Now we could build up the body filler right here to rebuild this corner, and now we have one small hole left to patch and this piece will fit perfect, so slide it behind the hole and I’m using a screw driver to help me get this body patch. In place, so our panel is sanded down and completely rust, free.

We indented it so that it has space for our body filler and we added our body patch plus we remove the rust from the back side and we coated it, so it won’t rust again. Now the last thing to do is to clean the area with alcohol or an adhesive remover, so we’ll have a completely clean surface for the next step, and that is applying our body filler. First, we’re going to use this fiberglass infused body filler, which is going to give the panel strength. Then we’re going to use this gold body filler, which is going to give us the smoothness.

So we could spray the panel now. Let me show you how to mix the body filler. You want to mix your filler and hardener on a non absorbent surface. That way your hardener doesn’t get trapped onto the surface you’re mixing on and not get mixed into the filler.

So what I like to do is grab some parchment paper and you could tape it down. So you have a flat non absorbent surface to mix on now. You do have to mix a specific ratio of body filler to hardener, and luckily it doesn’t have to be a perfect ratio.

You just have to get it close, so I have a little trick that works every time. So what you want to do is pour out your body fillers, so that it forms a circle and that circle should be a half an inch high. It doesn’t matter if your circle is tiny or if it’s large, as long as it’s a half an inch high.

This trick will work, and this is perfect now you want to grab your harder and always need this to make sure it’s well mixed and the correct amount of hardener is simply running a bead of hardener along the diameter of the circle. It’s really that easy and that’ll get you the correct ratio every time now. Let me show you some tips on mixing.

You don’t want to mix this like a cake. You don’t want to do it in a stirring motion because that’s going to add air to your filler, so instead notice how I gather all the filler and spread it out in a pressing motion to both mix the hardener in the filler and to force any air Out then, I just repeat the process. I gather it up and spread it out, gather it up and spread it out and if you’ve, never mixed filler before and you’re kind of unsure try mixing a batch just for practice and see how it all works.

Now mixing only takes about 45 seconds and you don’t want to mix too long, because you only have about five minutes until this hardens, but do be sure that you mix the filler. So that’s one consistent color. So it goes from this to this, where it’s completely mixed and you can’t see any hardener now when you’re done mixing, you don’t want to leave a big clump or a pile like that. A little trick is to spread this out thin, since this is undergoing an exothermic reaction.

It’s releasing heat so spreading it out thin allows the heat to release a lot easier, and that keeps this cooler which gives you more work time. So you have more time to apply this to the damage before it dries. It also allows the little trapped air bubbles to escape easier compared to being in a pile, so spreading it out is a simple trick that gives you way better results. Now, let’s apply this to the damage now at the damaged area, get a little filler on the spreader and press this filler hard into the damaged.

The idea is to press it against the metal, so there’s good contact, and so you force any air out after the first layer. You would apply more filler in thin layers and build up the filler, so it fills the damage and builds up to the height of the surrounding panel, this fillers for strength, so it doesn’t have to look perfect.

The next filler we’re going to use is what makes it smooth and, as you can see, we really didn’t use that much filler just enough to get a good coating on here and fill all the holes and, if you’re wondering how to clean your spreader, it’s actually Better not to keep the body filler on it and let it dry.

This is actually the easiest way to clean it and I’ll show you why, in a few minutes 15 to 20 minutes later, our filler is going to be completely dry. Now you want to grab your grit sandpaper on a sanding block and we’re going to start sanding. This there’s going to be a lot of dust. So what I like to do is I like to turn on a fan and what that’s going to do.

Is it’s going to blow all the dust out of your face, even though you’re wearing a dust mask, it’s still a good idea to keep the dust out of your face. So now, let’s send this body filler flat with the body. One thing that keep an eye out for is any body lines that you might have like this body line right here that runs to the end of the panel. We want to try to keep that body line, so it looks factory.

Suggested read: Water Heater Flush Service: Everything You Need to Know to Extend Your Unit's Lifespan

That means I’m going to spend a lot of time standing on this plane and a lot of time standing on that plane. The whole goal here is to sand down the body filler and try to shape it, so it makes it even with the surrounding body panel. Don’t worry about making it look perfect because we have another layer of that gold, finishing filler, that we’re going to use and that’s where we’re going to make it look real smooth, but for right now do the best you can to blend it into the body panel.

Next, we’re going to be using our gold filler, but before we do that, I want to show you real quick. Why told you to keep this dirty? All you have to do to clean. This up is bend it and snap that filler off and it should come off nice and clean from the spreader.

Now, let’s go and mix our gold filler, just as before, pour it out into a circle, half an inch high and run a bead of hardener along the diameter of the circle. Now use the same technique as before. To mix it so we don’t introduce air bubbles.

Good now, let’s go apply this for a smooth finish just like before we want to apply a thin first coat, forcing it into the repair. After that, you could build it up in thin layersso, it’s thicker than the body panel around it, which will allow us to sand it down even with the panel and once we’re done we’re going to, let it dry and 20 minutes later. Our final layer of body filler is hard, so we’re done with the body filler step.

Now, let’s move on to the sanding step, and we want to get this nice and smooth. So it looks like one whole panel now we’re going to start sanding with 80 grit. Sandpaper you want to hold the sanding block wet against the body panel, so it doesn’t create any waves or dips in the filler and you want to shape the body panel.

So it looks factory in this case. I’m sanding the wheel well edge so that it matches up with the bumper perfect. We have a nice and straight line and an even panel gap, all the way across beautiful and that’s looking so good. Now, let’s go from 80 grit to 180 grit and this sandpaper is going to give the filler a smoother finish and blend it into the body panel better after the hundred eighty grit.

This feels awesome. I can’t feel any transition at all when you run your finger across the bodywork. With your eyes closed, it feels like one complete panel, if you do happen to feel a bump or a ridge make sure you send that out any ridges and bumps that you can feel will show through the paint.

Now, at this point, you can move up to like a 320 grit and then 400 grit. But what I like to do is I like to use a glazing and spot putty which fills in all the little pinholes and imperfections that you can’t really see with the naked eye, but you’ll definitely be able to see if it gets painted. It’s really easy to use. You just put some on a spreader, and you want to just put a skim coat nice and thin, forcing it deep into the filler.

Now this isn’t going to fill any large holes only pinholes perfect. Now we just need to let this dry before we sand it with our 320 grit 15 minutes later. This is ready to go and we can start sanding with our 320 grit once it’s ended down, wiped down the work area.

So it’s clean and look at that. Does that look good or what I am so excited? I cannot wait to see this painted and that’s actually the next step, the painting step, so we’re going to be using a gray, filler primer, and this is going to be a filler primer, not just a regular primer. So it’s going to fill even more little imperfections that we can’t see right now before you paint anything since we’re working outside, and it’s all dusty. It’s a really good idea to grab something to blow all the dust away, whether it’s a leaf, blower compressed air.

Anything you have to get rid of the dust, so it doesn’t get all over our paint job and he definitely want to be wearing your dust mask for this one, because dust is everywhere after the dust settles, we want to do one more wipe down, make sure Our area is completely clean, good and now we’re ready to spray our primer filler. But we don’t want to get the primer filler on the good paint up here and if you just tape it off you’ll get harsh tape, lines which won’t look good. So a little trick is grab some paper and what you’re going to do is you’re going to tape.

It right above here and you’re going to bend it over and tape it down. So it curves just like that. Now this curved edge is going to help.

You spray your primer and it’s going to feather it in without creating a harsh line. Okay, so that’s a really cool little trick, so you don’t get a hard tape line. So let’s get three coats of primer on here and whenever painting follow the directions on the paint can, and that looks so good.

And now, let’s let this dry and let’s get this paper out of the way you can really see how that little trick of the curved paper creates this nice soft paint line. We don’t have a harsh tape line now at this point, you have two options: one! You could try painting the car yourself and that’s what I’m going to do so. You’re going to see the whole process, but if you’re not comfortable doing that, you saved all this money doing your own body work, you take it to a paint shop and it’ll.

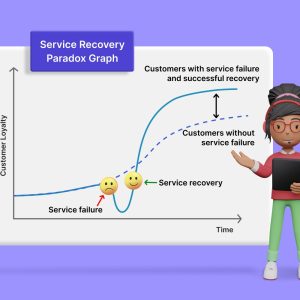

Suggested read: Unity Service Recovery: Restoring Operations and Customer Trust After Service Failures

Be a fraction of the price because they won’t have to do everything all they have to do is send this down a little bit tape off the wheel and around here and feather in that paint job. Now I went out and I bought spray paint that matches the paint code to this car, and then I also got the clear coat to go along with that. So we’re going to try spraypainting this and making it look good.

All right since we’re going to be painting this ourselves, let’s go and send that primer down. For this, we’re going to be using a 600 grit sandpaper, which is a pretty fine sandpaper, and the goal here is to smooth out this transition from our good paint to our primer and also sand the primer. So it’s nice and smooth make sure you use a sanding block, so everything is straight and even and don’t press down too hard, let the sandpaper do the work.

You also want to stand out into the paintwork, so we have a smooth transition layer for when we paint good now use alcohol or adhesive remover to get the area nice and clean for our final paint, job with our primer, nice and smooth, and about a two Inch scuff area that goes into the clear coat we’re ready for our first coat of base coat. So, let’s mask off the area using the curved paper technique to get a soft paint edge.

Okay, let’s paint this panel. The goal is light, even coats focus most of the painting in the filler area, but don’t try to put thick coats to cover it all at once, because then the paints are just going to run instead use light coats and it should look nice and even just Like that, once this dries to a matte finish, we’ll add our next coat.

Now you can see it’s a matte color and not shiny anymore, plus it’s a little bit lighter. So it’s time to add our next coat and we’re going to spray on this next coat. Slightly thicker than the last coat so we’re finishing up this second coat good, now again we’re going to let this coat dry to a matte finish.

And finally, we are on our last coat and at this point I think you get the idea of what we’re doing and with our base coat dry. Now we can move to our clear coat phase and this is actually a little trick. That’s really helpful in preventing orange peel, you put your clear coat bottle in the hottest water that you could get from your sink. That heats up the can and gives you a better spray pattern.

Just make sure you wipe down the cans, so you don’t get any water on your fresh paint job now we’re going to apply our first coat, which is going to be a relatively light coat, but we want full coverage similar to the base coat, we’re going to End up doing about three coats, and that is looking so good. That’s code number one and don’t worry about the paint color right now, because when the paint dries, it’s going to change color. Now, let’s do coat number two: let that dry and then do the final coat. This coat should be slightly thicker so that there’s less orange peelbut.

You don’t want it to be too thick, because that could cause the paint to run perfect so three coats later. This is looking awesome. I cannot wait for this to dry and I’m going to show you how to wet sand it to get rid of that orange peel and also blend it into the paint.

So after an hour, the paint’s dry enough, so that we could remove the paper and put the bumper back on now you’re asking yourself: why is there a lineup here? Why does it look all dusty? Well, that’s some of the clear coat that dries in the air and then lands on the paint. I don’t want to dust it off now. Cuz, that’s our brand new clear coat! That’s still curing so we’re just going to leave it like that and then, in a couple of days I’m going to come back and wet sand.

This and clean up all this dust and you’re going to see the results. This is going to. Look awesome. Alright, a few days later, let’s wet send this paint and finish this up.

Now, though, the instructions on the clear coat say you could sand it after 24 hours. I wanted to give this a couple of days to fully cure. So the first thing you want to do is you want to grab your soapy water and you want to spray down this entire area, then grab a microfiber towel and clean the area.

So there’s no dirt or debris left over that dirt and debris could rub into the paint while we’re wet sanding and create deeper, scratches next tape off any edges that you don’t want to sand like down here at the bumper so for the wet sanding process. Here’s the sandpaper we’re going to be using we’re going to be going from 1500 to 2000 to 3000 to 5000 grit. These are very fine sand papers. So we’re going to start out with our 1500 grit sandpaper, it’s wet.

It’s been soaking in soapy water. For about ten minutes and grab a sponge and wrap the sponge in the sandpaper, what the sponge is going to do is when you’re apply pressure, it’s going to even out the pressure, and it’s also going to conform with the curves of the car. So, let’s start the wet sanding. The first thing I want to do is spray down the entire area with soapy water, get it as wet as you can, and also make sure your sandpaper is wet.

You want to stand back and forth, not in circular motions and one other thing is our new clear coat is in this area down here, but we are going to want to come up into the factory clear coat so that we could have a nice smooth transition From factory clear coat to brand new clear coat and while you send you don’t want to focus in one spot like that, you want to use long, strokes and move along the entire body of the car once you’re done.

Suggested read: Munis Self Service: Your Complete Resource for Employee and Citizen Portal Access

Sanding spray, the area down with soapy water and then clean the area with a microfiber towel, so with our 1500 grit wet sand completely done now, we’re going to go and move to the 2000 grit so spray, the area down with soapy water sand. The entire panel smooth and clean it off with a towel.

Now, after our 2000 grit, we have a nice uniform haze. You could kind of see the new paint in the old paint right there, but I mean once we buff that it’s going to come right out. It’s going to look so good.

I cannot wait to finish this, so let’s go and wet sand with the 3000 grit sandpaper following the exact same process as we’ve been doing then dry it with your towel and finish up with the 5000 grit using the same exact process and finally, Clean the area off and let it dry completely so after our 5000 grit. Let’s remove that tape and we’re onto the last step, and that is to use a polish to bring back the shine in this paint. And you can do this by hand.

But I highly recommend using an electric buffer like this, because this is going to make your job so much easier and you’re really going to get a great shine out of the paintwork. So all you have to do is put a little polish on the wool pad and hand buff it into the paint work until it’s spread out then use the buffer on a low setting, keeping it under 1200 rpms keep that buffer moving.

So you don’t burn into the clear coat and you don’t have to press hard, let the buffer do all the work for you after you’re done buffing wipe down the panel to remove the polish and check out this shine. This came out awesome now, I’m by no means a professional painter or a professional bodywork guy, but the whole point of this video is to show you what you could do at home.

So this gives you a good idea of the results you could expect. If you were to take this on here’s, what we started with with all the rust damage and here’s what we ended up with a million times better – and not only does this look pretty good but, most importantly, we stopped the rust. So the owner could drive this vehicle for years to come, and that is how you repair rust damage.

So I hope the video was helpful if it was remember to give it a thumbs up and if you’re not a subscriber, consider, subscribing and finally, every tool and product I used in this video is linked in the description, so you could easily find it that way. You could do this yourself,