A vehicle’s onboard system designed to monitor the inflation status of its tires and alert the driver to significant pressure deviations is crucial for safety and optimal vehicle operation. This integrated technology typically employs sensors within each tire, transmitting real-time pressure data to a central control module. Upon detecting under- or over-inflation relative to predetermined thresholds, a warning indicator illuminates on the instrument panel, prompting driver awareness and action. For example, a passenger car might activate this warning if a tire’s pressure drops 25% below the manufacturer’s recommended level.

Maintaining proper tire inflation, facilitated by such technology, contributes significantly to enhanced vehicle handling, improved fuel efficiency, and extended tire lifespan. Historically, manual pressure checks were the norm, often neglected due to inconvenience. The advent of these automated monitoring capabilities has streamlined the process, improving driver awareness and promoting proactive maintenance. Correct tire pressure reduces the risk of blowouts, shortens braking distances, and minimizes uneven tread wear, all translating to safer and more economical driving.

The subsequent sections will delve into the common issues encountered with this essential automotive component, diagnostic procedures for identifying malfunctions, and best practices for its repair and maintenance, ensuring its continued reliability and contribution to overall vehicle safety and performance. These procedures will also discuss recalibration after tire replacement or repairs.

1. Sensor Malfunction

Sensor malfunction within a tire pressure monitoring system (TPMS) directly impacts the system’s ability to accurately relay tire pressure data. Such malfunctions necessitate diagnostic procedures and potential component replacement to restore proper system functionality, consequently requiring relevant maintenance steps.

-

Battery Depletion

TPMS sensors rely on internal batteries for power. Over time, these batteries deplete, rendering the sensor inoperable. A sensor with a dead battery will fail to transmit pressure readings, triggering a TPMS warning light and requiring sensor replacement. The lifespan of these batteries is often limited to 5-7 years, regardless of vehicle usage. This necessitates periodic system service.

Suggested read: Service: Master Your Service Brake System Now!

-

Physical Damage

Tire maintenance, road hazards, or impacts can cause physical damage to TPMS sensors. Valve stem damage, sensor housing cracks, or internal component failures can all result from physical trauma. Damaged sensors will typically provide inaccurate readings or cease functioning altogether, leading to TPMS alerts and the need for sensor replacement and system recalibration.

-

Corrosion and Environmental Factors

Exposure to road salt, moisture, and extreme temperatures can lead to corrosion within the sensor housing or on electrical connections. This corrosion can disrupt signal transmission, causing inaccurate pressure readings or complete sensor failure. In regions with harsh climates, sensor corrosion is a common issue that requires inspection and potential sensor replacement as part of regular TPMS maintenance.

-

Signal Interference

Although rare, external radio frequency interference can disrupt the communication between the TPMS sensor and the vehicle’s receiver. This interference may cause intermittent or inaccurate pressure readings, triggering false alerts. Troubleshooting signal interference typically involves identifying potential sources of interference and ensuring the TPMS receiver is functioning correctly. While not always a sensor malfunction itself, it can mimic such a fault, requiring diagnostic evaluation of the entire system.

The accurate functioning of TPMS sensors is paramount to the overall reliability of the tire pressure monitoring system. Addressing potential sensor malfunctions, whether due to battery depletion, physical damage, environmental factors, or signal interference, is a critical aspect of maintaining the integrity and effectiveness of the vehicle’s TPMS and ensuring safe vehicle operation. Replacing faulty sensors and correctly recalibrating the system as part of appropriate maintenance procedures ensures the vehicle operator is provided with accurate and timely tire pressure information.

2. System Calibration

Proper system calibration is a crucial aspect of the overall service and maintenance of a tire pressure monitoring system (TPMS). After tire rotation, tire replacement, or sensor replacement, the TPMS requires recalibration to accurately associate each sensor with its corresponding wheel position. Failure to calibrate the system can result in inaccurate tire pressure readings displayed to the driver and trigger unnecessary warnings or alerts. Calibration ensures the system correctly interprets the signals from each sensor and provides reliable information, thus fulfilling its safety function. Without calibration, the system may display the pressure from the front left tire as belonging to the rear right, for example, invalidating the system’s monitoring capabilities.

Several methods exist for TPMS recalibration, depending on the vehicle manufacturer and model. Some vehicles automatically learn the sensor positions after a short driving period, while others require a manual reset procedure using a diagnostic scan tool. The scan tool communicates with the vehicle’s computer to reprogram the sensor locations and clear any error codes. Ignoring the calibration step can lead to driver confusion and potentially compromise vehicle safety, as the driver may not be alerted to actual low-pressure situations. This can lead to reduced fuel efficiency, uneven tire wear, and increased risk of tire failure. A certified technician typically performs TPMS calibration as part of routine maintenance or after any tire-related service.

In summary, system calibration is an indispensable component of TPMS service. It ensures accurate sensor location mapping and reliable pressure readings. Neglecting this step can undermine the system’s effectiveness, potentially jeopardizing driver safety and vehicle performance. Automotive service providers should emphasize the importance of TPMS calibration after any intervention affecting the tires or sensors to maintain the integrity and functionality of this safety system.

3. Diagnostic Trouble Codes

Diagnostic Trouble Codes (DTCs) are integral to servicing a tire pressure system. These codes, generated by the vehicle’s computer, pinpoint specific malfunctions within the TPMS, guiding technicians in accurate diagnostics and repair. The presence and interpretation of relevant DTCs are paramount to resolving system faults efficiently.

-

Sensor Communication Errors

DTCs such as C0750, C0755, C0760, and C0765 indicate a loss of communication with one or more TPMS sensors. These codes suggest a potential problem with the sensor itself, the wiring harness connecting the sensor to the TPMS control module, or the control module itself. For instance, code C0750 might signify a failure in the front left tire sensor’s ability to transmit pressure data. Corrective action involves verifying sensor functionality, inspecting wiring for damage, and potentially replacing a faulty sensor or control module.

-

Low Sensor Battery

TPMS sensors are battery-powered devices with a finite lifespan. A DTC, such as C0710, may signal a low battery condition in one or more sensors. When this code appears, it indicates that the sensor’s battery voltage has dropped below a minimum threshold, necessitating sensor replacement. Ignoring this code can lead to intermittent or complete sensor failure, compromising the TPMS’s ability to monitor tire pressure accurately.

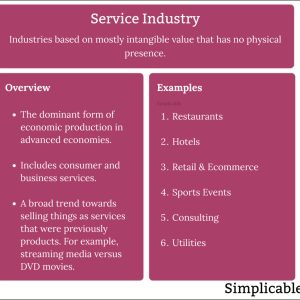

Suggested read: Comprehensive Guide to the Service Industry Definition

-

Incorrect Sensor Identification

After tire rotation or sensor replacement, the TPMS control module must learn the new sensor locations. If this process is not performed correctly, or if a sensor is not compatible with the vehicle, DTCs such as C0715 (Tire Pressure Sensor ID Incorrect) may be triggered. This code indicates a mismatch between the sensor ID stored in the control module and the actual sensor ID transmitting data. Resolving this issue requires reprogramming the TPMS control module to recognize the correct sensor IDs.

-

Pressure Reading Out of Range

DTCs such as C0700 indicate a tire pressure reading outside the expected range. This could be due to an overinflated or underinflated tire, or a faulty sensor providing inaccurate data. For example, a reading substantially lower than the recommended pressure, accompanied by this DTC, could indicate a tire leak or sensor malfunction. Technicians must verify the actual tire pressure and assess the sensor’s accuracy to determine the root cause and perform appropriate repairs.

In conclusion, the interpretation and resolution of Diagnostic Trouble Codes are essential for proper tire pressure system service. These codes provide valuable information regarding the nature and location of faults within the TPMS, enabling technicians to perform targeted repairs and ensure the system functions correctly. A thorough understanding of common TPMS DTCs is a prerequisite for effective diagnosis and repair, contributing to vehicle safety and optimal tire performance.

4. Battery Life

The operational lifespan of a tire pressure monitoring system (TPMS) is intrinsically linked to the battery life of its constituent sensors. Each sensor, typically housed within the tire or valve stem, relies on a non-replaceable battery to transmit pressure and temperature data wirelessly to the vehicle’s central control module. The finite capacity of these batteries dictates the overall service life of the TPMS, generally ranging from five to ten years, irrespective of vehicle usage. When a sensor’s battery depletes, the sensor ceases to function, triggering a warning light on the instrument panel and necessitating sensor replacement to restore system functionality. Consequently, battery longevity directly influences the frequency and cost of TPMS maintenance.

The depletion of a TPMS sensor battery exemplifies the cause-and-effect relationship between battery life and system functionality. For instance, a vehicle equipped with a TPMS manufactured in 2018 might experience sensor failures due to battery exhaustion starting in 2023 or later. Factors such as ambient temperature extremes and the frequency of data transmission can accelerate battery drain. Regular tire rotations, while beneficial for tire wear, do not extend sensor battery life. The inability to replace the battery separately from the sensor mandates replacement of the entire sensor unit, highlighting the economic and practical implications for vehicle owners. Aftermarket TPMS sensors may offer varying battery life expectancies, potentially impacting long-term maintenance costs.

In summary, battery life constitutes a critical limiting factor in the service life of a tire pressure monitoring system. Understanding the typical lifespan of TPMS sensor batteries and the factors influencing their degradation is essential for effective vehicle maintenance planning. The eventual need for sensor replacement due to battery exhaustion represents a recurring maintenance consideration for vehicles equipped with this technology. The integration of more energy-efficient sensors and potential advancements in battery technology could extend TPMS lifespan, reducing maintenance demands and enhancing the long-term value of these safety systems.

5. Proper Inflation

The maintenance and functionality of a tire pressure system are inextricably linked to the concept of proper inflation. A functional TPMS is designed to alert drivers to deviations from the manufacturer’s recommended tire pressure, highlighting the critical role proper inflation plays in vehicle safety and performance.

-

Optimized Tire Performance

Maintaining the correct tire pressure, as monitored by the TPMS, ensures optimal tire contact with the road surface. This results in enhanced handling, braking efficiency, and cornering stability. Underinflated tires increase the risk of tire failure, reduced fuel economy, and compromised vehicle control. A properly functioning TPMS alerts the driver to underinflation, enabling corrective action to maintain optimal tire performance and avoid these negative consequences. For instance, a sedan with tires consistently inflated 5 PSI below the recommended pressure experiences a noticeable decrease in fuel efficiency and increased tire wear. The TPMS flags this deviation, prompting the driver to reinflate the tires to the specified level.

-

Extended Tire Lifespan

Consistent underinflation or overinflation accelerates tire wear. Underinflated tires flex excessively, generating heat and leading to premature wear on the tire shoulders. Overinflated tires reduce the contact patch with the road, causing the center of the tread to wear more quickly. The TPMS, by monitoring tire pressure, promotes proper inflation practices, thereby contributing to extended tire lifespan. A commercial vehicle fleet equipped with a TPMS, coupled with regular tire pressure checks guided by the system’s alerts, typically experiences a significant reduction in tire replacement costs compared to fleets without such monitoring.

-

Enhanced Fuel Efficiency

Properly inflated tires reduce rolling resistance, the force required to keep the tires moving. Lower rolling resistance translates directly into improved fuel efficiency. Underinflated tires increase rolling resistance, requiring the engine to work harder and consume more fuel. A functional TPMS that alerts drivers to underinflation conditions encourages timely pressure adjustments, optimizing fuel economy. Studies have shown that maintaining correct tire pressure, as facilitated by a TPMS, can improve fuel efficiency by as much as 3%, resulting in substantial fuel savings over the lifespan of a vehicle.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

-

Improved Vehicle Safety

Properly inflated tires contribute significantly to vehicle safety by ensuring optimal handling, braking performance, and reduced risk of tire failure. Underinflated tires are more susceptible to overheating and blowouts, particularly at high speeds. A TPMS serves as a critical safety feature by providing real-time tire pressure monitoring and alerting the driver to potentially dangerous conditions. Emergency vehicles, such as ambulances and fire trucks, rely heavily on TPMS to ensure their tires are properly inflated, minimizing the risk of tire-related accidents during critical operations. The reliable functioning of the TPMS provides an added layer of safety for both the driver and other road users.

These facets illustrate the integral role a functional tire pressure system plays in promoting and maintaining proper inflation. Through accurate monitoring and timely alerts, the system not only optimizes tire performance, lifespan, and fuel efficiency but also significantly enhances vehicle safety. Routine service and maintenance of the TPMS are crucial to ensure it continues to perform its essential function of promoting proper tire inflation.

Frequently Asked Questions

The following addresses common inquiries concerning the maintenance, operation, and potential issues related to a vehicle’s tire pressure monitoring system (TPMS). Clarity regarding this technology is crucial for both driver safety and responsible vehicle upkeep.

Question 1: What constitutes a ‘service tire pressure system’ alert?

A “service tire pressure system” alert indicates a detected malfunction within the TPMS. This signifies a deviation from normal operational parameters, not merely a low tire pressure condition, potentially involving sensor failures, communication issues, or system calibration errors. Diagnostic evaluation is necessary to determine the root cause.

Question 2: Can a “service tire pressure system” warning be ignored?

Ignoring a “service tire pressure system” warning is inadvisable. While the tires may appear visually inflated, the underlying problem could compromise the system’s ability to accurately detect and alert the driver to future pressure losses, potentially leading to unsafe driving conditions.

Question 3: Does tire rotation require “service tire pressure system” recalibration?

Yes, tire rotation typically necessitates TPMS recalibration. The system must relearn the new positions of each sensor to accurately display tire pressures at the correct locations. Failure to recalibrate can result in mismatched pressure readings and inaccurate alerts.

Question 4: What is the typical lifespan of a TPMS sensor requiring “service tire pressure system” attention?

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

The average lifespan of a TPMS sensor battery ranges from five to ten years. Environmental factors and usage patterns can influence this duration. Battery depletion is a common reason for a “service tire pressure system” alert and requires sensor replacement.

Question 5: Is “service tire pressure system” diagnosis a do-it-yourself task?

While basic tire pressure checks can be performed independently, diagnosing a “service tire pressure system” alert generally requires specialized diagnostic equipment and expertise. Improper handling could damage the system or lead to inaccurate conclusions.

Question 6: How does “service tire pressure system” maintenance impact fuel efficiency?

A properly functioning TPMS contributes to optimal fuel efficiency by ensuring tires are inflated to the recommended pressure. Underinflated tires increase rolling resistance, leading to higher fuel consumption. Addressing a “service tire pressure system” alert helps maintain correct tire inflation and maximize fuel economy.

In summary, diligent attention to a “service tire pressure system” alert is critical for vehicle safety and optimal performance. Seeking professional diagnosis and repair is often the most effective approach to resolving these issues and maintaining the integrity of the TPMS.

The subsequent section will address troubleshooting techniques for common TPMS problems.

Service Tire Pressure System

The following constitutes a set of guidelines for preserving the integrity and functionality of a vehicle’s tire pressure monitoring system (TPMS). Adherence to these principles enhances road safety and vehicle performance.

Tip 1: Regular Visual Inspections

Periodically examine tires for signs of uneven wear or damage. Discrepancies can indicate underlying pressure issues undetectable by the TPMS, potentially masking sensor malfunctions. Address anomalies promptly to prevent further complications.

Tip 2: Prompt Response to Alerts

Any “low tire” or “service TPMS” indicator demands immediate attention. Investigate the cause before resuming travel. Continuing to drive with a malfunctioning or alerting TPMS can compromise vehicle control and tire integrity.

Tip 3: Professional Diagnostic Evaluations

If the “service tire pressure system” indicator persists despite proper tire inflation, seek professional diagnostic assessment. Certified technicians possess the equipment and expertise to identify underlying sensor, communication, or calibration issues.

Tip 4: Post-Tire Service Recalibration

After tire rotation, replacement, or repair, ensure the TPMS is recalibrated. This step is crucial for maintaining accurate pressure readings and preventing false alerts. Verify recalibration has been completed by confirming pressure displays match actual tire positions.

Suggested read: Ultimate Guide to Service Marks: Protecting Your Brand Identity

Tip 5: Sensor Battery Considerations

Recognize that TPMS sensors possess a finite battery life, typically spanning five to ten years. Proactive replacement of all sensors at the recommended interval mitigates the risk of individual sensor failures and ensures system reliability.

Tip 6: Avoid Aftermarket Incompatibilities

When replacing TPMS sensors, utilize components certified for compatibility with the vehicle’s make and model. Non-compliant sensors can generate communication errors, trigger false alerts, and impede overall system functionality.

Tip 7: Heed Environmental Factors

Extreme temperatures can influence tire pressure. Monitor pressure fluctuations during seasonal changes and adjust inflation accordingly. The TPMS will alert to significant pressure losses, but manual adjustments may be necessary to maintain optimal levels.

Consistent adherence to these maintenance practices ensures the tire pressure monitoring system operates reliably and effectively. Proactive care enhances road safety and extends tire lifespan, minimizing potential hazards.

The concluding section provides information about potential costs associated with TPMS service.

Service Tire Pressure System

The preceding discussion has explored the multifaceted aspects of the “service tire pressure system” indicator, ranging from the underlying causes of system malfunctions to essential maintenance practices. Key areas addressed include sensor failures, calibration procedures, diagnostic trouble codes, battery life considerations, and the critical relationship between proper inflation and TPMS functionality. A thorough understanding of these elements empowers vehicle owners and service professionals to address TPMS issues effectively, mitigating potential risks and optimizing vehicle performance.

Given the direct correlation between a functional tire pressure monitoring system and vehicle safety, diligent attention to TPMS maintenance remains paramount. Prompt diagnosis and resolution of any “service tire pressure system” alert are not merely advisable but a responsible measure toward ensuring safe operation and extending the lifespan of a vehicle’s tires. Consistent adherence to recommended maintenance procedures, including regular inspections and professional evaluations, contributes significantly to overall road safety and operational efficiency. The integrity of the TPMS directly impacts driver awareness and the ability to respond appropriately to potentially hazardous tire conditions.