The vehicle’s electronic stability control system monitors and adjusts braking and engine torque to help maintain directional control. When a malfunction occurs within this system, a notification, often displayed on the instrument panel, alerts the driver to a potential issue requiring attention. This notification indicates that the system may not be functioning correctly, potentially compromising the vehicle’s ability to mitigate skidding or loss of control in challenging driving conditions.

The effective functioning of this system is critical for driver safety, particularly in adverse weather or emergency maneuvers. Its evolution stems from ongoing efforts to enhance vehicle safety and reduce accidents caused by loss of control. Addressing reported issues promptly can prevent more significant problems and ensure the vehicle operates within its intended safety parameters. Ignoring such warnings could increase the risk of accidents, particularly in situations requiring precise vehicle handling.

The subsequent sections will delve into the diagnostic procedures, potential causes, and repair strategies associated with malfunctions in this vital vehicle safety component. This includes examining common sensor failures, wiring issues, and control module problems that can trigger the warning, along with methods for troubleshooting and resolving these issues.

1. Sensor Malfunctions

Sensor malfunctions are a primary contributor to the activation of the “service stabilitrak” warning. The system relies on a network of sensors, including wheel speed sensors, yaw rate sensors, and steering angle sensors, to continuously monitor the vehicle’s dynamics. These sensors provide data to the electronic control unit (ECU), which then calculates the vehicle’s stability and makes adjustments to braking and engine torque as needed. When a sensor provides inaccurate or absent data, the ECU cannot reliably assess the vehicle’s condition. For example, a malfunctioning wheel speed sensor may incorrectly report wheel slippage, leading the system to inappropriately engage the brakes, triggering the warning. The system may also be disabled to prevent unintended interventions, thus activating the “service stabilitrak” notification.

The consequence of sensor failure extends beyond the initial warning light. It can degrade the vehicle’s ability to maintain stability in critical situations, such as sudden maneuvers or slippery road conditions. Consider a scenario where a yaw rate sensor fails. This sensor measures the vehicle’s rotation around its vertical axis. Without accurate yaw rate data, the system might not correctly detect a skid, and therefore, would fail to apply corrective actions. This deficiency could significantly increase the risk of loss of control, especially in emergency situations. Regularly diagnosing and replacing faulty sensors is, therefore, critical for ensuring that the vehicle’s stability control system functions as intended.

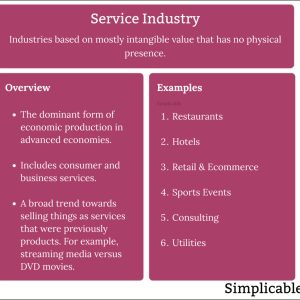

Suggested read: Comprehensive Guide to the Service Industry Definition

In conclusion, sensor malfunctions directly and negatively impact the efficacy of the stability control system, leading to the “service stabilitrak” message and potentially compromising vehicle safety. Timely identification and correction of sensor-related issues are essential for maintaining the intended functionality and safety benefits of the system. Proper diagnostic procedures and the use of reliable replacement sensors are crucial for ensuring the continued effective operation of the vehicle’s stability control system.

2. Wiring Integrity

Compromised wiring integrity directly impacts the effectiveness of the stability control system and can trigger the “service stabilitrak” message. The system relies on continuous, reliable communication between its various sensors, the control module, and actuators. This communication is facilitated by a network of wires and connectors. Damage, corrosion, or loose connections within this wiring network can disrupt the flow of data, leading to inaccurate readings or a complete loss of signal. For example, a corroded connector on a wheel speed sensor wire can intermittently interrupt the signal, causing the system to believe that the wheel is slipping when it is not. This erroneous information can then trigger the system to apply braking force unnecessarily, activating the “service stabilitrak” warning.

Maintaining wiring integrity is, therefore, paramount to the proper function of the stability control system. Regular inspections for signs of damage, such as frayed insulation, exposed wires, or corroded terminals, are crucial. Addressing these issues promptly can prevent more significant problems and ensure that the system operates as intended. For instance, rodent damage to wiring harnesses is a common issue that can lead to intermittent faults and system failures. Repairing or replacing damaged sections of the harness is necessary to restore proper communication and prevent the false activation of the “service stabilitrak” warning. Similarly, ensuring that all connectors are securely fastened and free from corrosion is essential for maintaining a stable and reliable electrical connection.

In conclusion, the integrity of the wiring harness is integral to the performance of the stability control system. Poor wiring conditions can cause inaccurate sensor readings, leading to inappropriate system responses and the triggering of the “service stabilitrak” message. Proactive inspection and maintenance of the wiring are critical steps in preventing system malfunctions and ensuring the vehicle’s stability control system operates effectively, thereby enhancing driver safety. Regular attention to wiring integrity serves as a fundamental aspect of responsible vehicle maintenance.

3. Control Module

The control module, often referred to as the Electronic Control Unit (ECU) or Stability Control Module, serves as the central processing unit for the vehicle’s stability control system. This module receives data from various sensors, interprets this information, and then commands the braking system and engine to take corrective actions aimed at maintaining vehicle stability. The module’s role is critical; any malfunction within it can directly trigger the “service stabilitrak” warning. For instance, if the module’s internal processing capabilities are compromised due to electrical surges or internal component failure, it may misinterpret sensor data or fail to execute necessary corrections. This can lead to the system either inappropriately activating stability control measures or, conversely, failing to activate them when needed, both conditions resulting in the activation of the warning.

Further, the control module’s software plays a crucial role in its operation. Software corruption or glitches can cause the module to operate erratically or to misdiagnose system errors. This can manifest as the “service stabilitrak” message appearing intermittently, or the system becoming entirely inoperative. For example, a software update that is improperly installed can corrupt the existing code, leading to communication errors between the module and other vehicle systems. Addressing such issues often requires reflashing the module with the correct software or, in severe cases, replacing the entire unit. Moreover, the control module’s diagnostic capabilities enable it to detect faults within the broader stability control system. When a sensor or actuator malfunctions, the module will typically store diagnostic trouble codes (DTCs) that can be accessed with a scan tool, providing technicians with valuable information for troubleshooting.

In summary, the control module is an indispensable component of the stability control system, acting as the brain behind its operation. Malfunctions within the module, whether stemming from hardware failures or software corruption, can directly trigger the “service stabilitrak” warning. Proper diagnosis and repair, including software updates or module replacement, are crucial for restoring the system’s functionality and ensuring the vehicle’s stability control system operates as intended, thus enhancing driver safety. Understanding the intricacies of the control module’s operation is essential for accurate and effective troubleshooting.

4. Braking System

The vehicle’s braking system forms a critical element of the electronic stability control system. Its proper function is paramount to the effective operation of “service stabilitrak.” When this system detects a loss of control, it often selectively applies the brakes to individual wheels to help steer the vehicle back on its intended path. Any issue within the braking system can directly impact the performance of the stability control, potentially triggering a warning.

-

Hydraulic Pressure

The hydraulic pressure within the braking system must be adequate and consistent to allow for precise brake application by the stability control system. Insufficient pressure, caused by a failing master cylinder or leaks in the brake lines, can prevent the system from applying the necessary braking force. For example, if the system attempts to correct a skid by applying the brake on one wheel but the hydraulic pressure is too low, the corrective action will be ineffective, and a warning may be triggered. This can result in reduced stability control effectiveness, particularly in emergency situations.

-

ABS Functionality

The Anti-lock Braking System (ABS) is closely integrated with the stability control system. ABS prevents wheel lockup during hard braking, allowing the driver to maintain steering control. If the ABS system malfunctions, it can interfere with the stability control’s ability to selectively apply brakes. For instance, a faulty ABS sensor can provide incorrect data to the stability control module, leading to inappropriate braking interventions or a complete disabling of the system, activating the warning. A properly functioning ABS is essential for the stability control system to operate effectively.

-

Brake Wear and Condition

The condition of the brake pads and rotors directly affects the stability control system’s ability to control the vehicle. Worn brake pads or damaged rotors can reduce braking effectiveness, increasing the distance required to stop the vehicle. This can compromise the stability control system’s ability to prevent skidding or loss of control. For example, if the system attempts to correct a slide by applying the brakes, but the worn brake pads provide insufficient friction, the correction will be less effective, and the driver may experience a diminished sense of control. Regular brake maintenance is, therefore, vital for maintaining optimal stability control performance.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

-

Wheel Speed Sensors

Wheel speed sensors are crucial components of both the ABS and stability control systems. These sensors monitor the rotational speed of each wheel and provide data to the control module. If a wheel speed sensor fails or provides inaccurate readings, the stability control system may not be able to accurately detect wheel slippage or loss of traction. This can result in the system failing to activate when needed, or activating inappropriately, potentially triggering the warning. Reliable wheel speed sensor data is essential for the accurate and timely activation of the stability control system.

The interconnectedness of these braking system elements underscores the necessity for diligent maintenance and inspection. A properly functioning braking system is not merely a component; it is a prerequisite for the effective and reliable operation of the stability control system. Any compromise within the braking system can cascade into broader stability control issues, ultimately diminishing the vehicle’s ability to maintain directional control and increasing the risk of accidents. Routine checks and prompt repairs are essential for upholding the integrity of both the braking and stability control systems.

5. Engine Torque

Engine torque management is an integral function within the electronic stability control system. The system actively modulates engine torque output to assist in maintaining vehicle stability during challenging driving conditions. When the system detects a potential loss of control, such as wheel slippage during acceleration or cornering, it can intervene by reducing engine torque. This reduction in torque helps to restore traction and prevent the vehicle from spinning out or losing directional control. The precise and coordinated adjustment of engine torque is essential for the effective operation of the stability control system. For instance, if a vehicle begins to oversteer during a turn, the system might reduce engine torque to the rear wheels to help the driver regain control. A failure within the engine torque management system can directly trigger a “service stabilitrak” warning, indicating that the system is not functioning as intended.

The engine control unit (ECU) governs engine torque output, and it communicates with the stability control module to coordinate torque reduction. This communication relies on accurate sensor data and proper calibration of the engine management system. Issues such as faulty sensors, wiring problems, or ECU malfunctions can disrupt the communication between these systems, leading to inaccurate torque management and triggering the warning. Furthermore, modifications to the engine or drivetrain that alter the engine’s torque characteristics can also negatively impact the stability control system’s performance. These modifications can create a mismatch between the expected and actual torque output, causing the system to react inappropriately or to disengage entirely.

In summary, the effective management of engine torque is critical for the proper functioning of the stability control system. Disruptions to engine torque control, whether due to sensor failures, communication issues, or modifications to the engine, can trigger the “service stabilitrak” warning and compromise the vehicle’s ability to maintain stability. Therefore, when troubleshooting the “service stabilitrak” message, it is essential to consider the engine torque management system as a potential source of the problem. A comprehensive diagnostic approach that includes checking sensor data, verifying ECU communication, and assessing engine modifications is necessary to resolve these issues and ensure the vehicle’s stability control system operates as intended.

Frequently Asked Questions

This section addresses common inquiries regarding the system malfunction indication in vehicles. The information provided aims to clarify its causes, potential consequences, and recommended actions.

Question 1: What does the “service stabilitrak” message signify?

The appearance of the “service stabilitrak” message indicates that the vehicle’s electronic stability control system has detected a malfunction. This system is designed to enhance vehicle stability, and its impaired function necessitates investigation.

Question 2: Is it safe to operate a vehicle displaying the “service stabilitrak” message?

While the vehicle remains operational, the compromised stability control system reduces its ability to prevent skidding or loss of control. Therefore, driving should be cautious, particularly under adverse conditions, until the system is repaired.

Question 3: What are the potential causes of the “service stabilitrak” message?

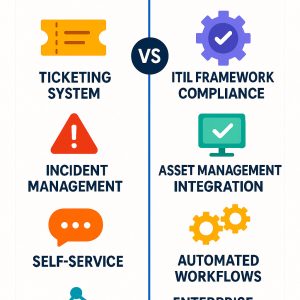

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

Numerous factors can trigger the message, including sensor malfunctions, wiring issues, control module failures, problems with the braking system, and engine torque irregularities. Diagnostic procedures are required to pinpoint the specific cause.

Question 4: Can the “service stabilitrak” message be resolved by restarting the vehicle?

In some instances, a temporary glitch may cause the message to appear. Restarting the vehicle could clear the message. However, if the message persists or reappears, it indicates a genuine problem requiring professional attention.

Question 5: What diagnostic steps are involved in addressing a “service stabilitrak” message?

Technicians typically employ scan tools to retrieve diagnostic trouble codes (DTCs) stored by the vehicle’s computer. These codes provide insights into the specific system components experiencing issues. Further testing and inspection are then conducted based on the retrieved codes.

Question 6: What are the potential consequences of ignoring a “service stabilitrak” message?

Ignoring the warning can lead to diminished vehicle stability, increasing the risk of accidents, particularly in challenging driving situations. Furthermore, unresolved issues may escalate, resulting in more extensive and costly repairs.

Prompt attention to this warning is advisable. A qualified technician should assess the vehicle to ensure the electronic stability control system functions as intended.

The following sections will explore specific diagnostic procedures, repair strategies, and preventative maintenance measures to maintain the vehicle’s stability control system.

Essential Considerations for System Integrity

The following guidelines serve to maintain the operational effectiveness of the vehicle’s electronic stability control system. Adherence to these principles helps ensure consistent performance and safety.

Suggested read: Ultimate Guide to Service Marks: Protecting Your Brand Identity

Tip 1: Regular Diagnostic Scans

Conduct routine diagnostic scans of the vehicle’s electronic systems. This proactive approach facilitates the early detection of potential issues within the system, even before noticeable symptoms manifest. Utilize a scan tool to check for stored diagnostic trouble codes (DTCs) related to the system.

Tip 2: Meticulous Sensor Maintenance

Ensure the proper functioning of all associated sensors, including wheel speed sensors, yaw rate sensors, and steering angle sensors. Verify that these sensors are free from debris, properly aligned, and functioning within specified parameters. Replace any sensors exhibiting signs of damage or providing inconsistent readings.

Tip 3: Vigilant Wiring Inspection

Perform regular inspections of the system’s wiring harness and connectors. Check for signs of corrosion, fraying, or loose connections. Address any wiring issues promptly to maintain reliable communication between the sensors, control module, and actuators. Apply dielectric grease to connectors to prevent corrosion and ensure a secure electrical connection.

Tip 4: Strategic Control Module Monitoring

Monitor the performance of the control module. Be attentive to any unusual behavior, such as intermittent system failures or erratic operation. If a control module malfunction is suspected, consult a qualified technician for diagnostic testing and potential reprogramming or replacement.

Tip 5: Comprehensive Brake System Maintenance

Maintain the vehicle’s braking system to ensure optimal performance. Check brake pad thickness, rotor condition, and brake fluid levels regularly. Address any brake system issues, such as leaks or worn components, promptly to maintain consistent braking performance and support the stability control system’s effectiveness.

Tip 6: Proper Tire Management

Ensure that tires are properly inflated, balanced, and aligned. Uneven tire wear or improper inflation can negatively impact the system’s ability to accurately detect and respond to changes in vehicle stability. Rotate tires regularly to promote even wear and extend their lifespan. Adhere to the vehicle manufacturer’s recommended tire specifications.

Tip 7: Caution with Vehicle Modifications

Exercise caution when considering modifications to the vehicle’s suspension, engine, or drivetrain. These modifications can alter the vehicle’s handling characteristics and potentially interfere with the stability control system’s intended operation. Consult with a qualified technician before making any modifications to ensure compatibility and avoid compromising the system’s effectiveness.

Suggested read: The Essential Guide to Finding a Top-Notch Service Professor

Tip 8: Regular Fluid Checks

Check fluid levels, particularly brake fluid. Low or contaminated fluids can impair system function, leading to reduced effectiveness. Ensure that fluids are within the manufacturer’s recommended levels and are free from contamination.

These proactive measures contribute to the longevity and reliability of the system, maximizing vehicle safety and performance. Consistent adherence to these practices minimizes the risk of system malfunction and ensures continued operational readiness.

The subsequent section concludes this exploration, offering a final summary and reinforcing the importance of maintaining the electronic stability control system.

Conclusion

This exploration has detailed the functionalities associated with the message, its causes, and essential considerations for maintaining system integrity. Sensor malfunctions, wiring integrity, control module operation, braking system health, and engine torque management all contribute significantly to its overall effectiveness. Comprehensive understanding and diligent maintenance are paramount for ensuring optimal performance.

The presence of a “service stabilitrak” indication should not be dismissed. Rather, it should prompt immediate attention, initiating diagnostic procedures and, if necessary, repairs. The integrity of this system directly affects vehicle safety, and prioritizing its proper function is a responsible course of action for any vehicle operator.