This process involves the inspection, diagnosis, and repair of the system that regulates engine power by electronically controlling the throttle valve. The system’s function is essential for maintaining optimal engine performance, fuel efficiency, and emission control. For example, if the engine exhibits erratic idling or a lack of responsiveness to the accelerator pedal, this system may require attention.

Proper maintenance ensures the vehicle operates as intended, providing a smooth and predictable driving experience. Addressing issues promptly can prevent more serious mechanical problems, potentially saving on future repair costs. The advent of this technology marked a significant shift from mechanically linked throttle systems, allowing for greater precision and integration with other vehicle control systems.

The following sections will delve into specific diagnostic procedures, common failure modes, and effective repair strategies to ensure optimal system performance.

1. Diagnosis

The diagnostic process is the cornerstone of effective maintenance for the electronic throttle control system. Accurate assessment of system functionality is paramount to identify and rectify performance deviations.

-

Fault Code Retrieval and Interpretation

Modern vehicle systems store diagnostic trouble codes (DTCs) that provide initial indications of system malfunctions. Accurate interpretation of these codes, using manufacturer-specific documentation, is crucial. For instance, a P0121 code may indicate a throttle position sensor issue, but further investigation is required to determine the precise cause, whether it be a faulty sensor, wiring issue, or mechanical problem within the throttle body.

-

Sensor Data Analysis

Diagnostic tools allow technicians to monitor real-time data from various sensors within the system, such as the throttle position sensor (TPS), accelerator pedal position sensor (APPS), and manifold absolute pressure (MAP) sensor. Analyzing these data streams enables the identification of anomalies, such as erratic sensor readings or discrepancies between expected and actual values. For example, a sudden drop in TPS voltage when the accelerator pedal is depressed could point to a failing sensor.

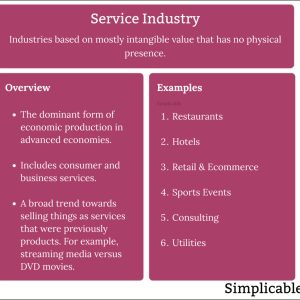

Suggested read: Comprehensive Guide to the Service Industry Definition

-

Component Testing

Individual components can be tested using specialized tools to assess their functionality. The throttle body motor, for example, can be directly powered to check its ability to open and close the throttle plate smoothly. Resistance measurements can be taken on sensors to verify they are within specified ranges. Disconnecting and testing the resistance of the throttle motor windings can quickly determine if there is an open or short circuit.

-

Wiring and Connector Inspection

A thorough visual inspection of wiring harnesses and connectors is essential. Damaged wiring, corroded connectors, or loose connections can disrupt signal transmission and cause system malfunctions. For instance, a chafed wire near the throttle body could intermittently short to ground, causing unpredictable engine behavior.

The aforementioned diagnostic facets collectively provide a systematic approach to identifying the root cause of electronic throttle control system issues, thereby facilitating effective repairs and ensuring optimal vehicle performance. Comprehensive application of these methods will save both time and resources during the repair process.

2. Calibration

Calibration is a critical aspect of maintaining the electronic throttle control system’s functionality. The process involves aligning the system’s electronic parameters with the engine’s mechanical state to ensure optimal performance. Incorrect calibration can lead to various issues, including poor idle quality, reduced fuel efficiency, and compromised engine response. For example, after replacing the throttle body or performing significant engine work, the system requires recalibration to accurately interpret the throttle position sensor signals. Without proper calibration, the engine control unit (ECU) may misinterpret the throttle position, resulting in inappropriate fuel delivery and ignition timing. This scenario will cause the engine to run erratically, potentially triggering diagnostic trouble codes.

Calibration procedures typically involve using a diagnostic scan tool to reset the throttle position sensor’s learned values. The scan tool communicates with the ECU, allowing a technician to perform a throttle position relearn procedure. During this process, the ECU learns the minimum and maximum throttle positions, ensuring accurate control across the entire throttle range. Consider a situation where the throttle body has been cleaned. Even after a thorough cleaning, residual buildup or slight changes in the throttle plate position can affect the TPS readings. Calibration corrects this variance, ensuring accurate throttle control. It also applies to the accelerator pedal position sensor (APPS). The APPS data that does not agree with the TPS can cause drivability issues.

In summary, calibration is an indispensable step in the maintenance and repair of the electronic throttle control system. It ensures the system operates within specified parameters, maintaining optimal engine performance and preventing potential malfunctions. Failure to perform calibration after component replacement or repair can lead to compromised vehicle operation and further diagnostic challenges. Understanding the cause-and-effect relationship between calibration and system performance is crucial for effective vehicle maintenance.

3. Component Testing

Effective upkeep of the electronic throttle control system necessitates rigorous component testing to verify operational integrity. Such testing ensures that individual parts function within specified parameters, contributing to overall system reliability and performance. This diagnostic step becomes essential when addressing performance issues or during preventative maintenance procedures.

-

Throttle Position Sensor (TPS) Testing

The Throttle Position Sensor (TPS) relays the throttle plate’s angular position to the engine control unit (ECU). Testing involves measuring resistance across specific terminals while manually actuating the throttle. Irregular resistance, open circuits, or short circuits indicate a faulty TPS. A failing TPS can cause erratic idling, hesitation upon acceleration, and diagnostic trouble codes. Precise testing methods, often employing a multimeter or oscilloscope, ensure the sensor’s readings correspond accurately to the throttle position.

-

Throttle Body Motor Testing

The throttle body motor, a DC motor, governs the throttle plate’s opening and closing. Testing verifies the motor’s ability to smoothly control the throttle plate across its full range of motion. Applying voltage directly to the motor terminals confirms functionality. Measuring the motor’s winding resistance identifies potential short circuits or open circuits. Issues with the motor can result in a complete loss of throttle control, triggering failsafe modes within the ECU.

-

Accelerator Pedal Position Sensor (APPS) Testing

The Accelerator Pedal Position Sensor (APPS) communicates the driver’s throttle input to the ECU. Testing involves monitoring voltage output from the sensor as the accelerator pedal is depressed and released. Variations in voltage, or the absence of signal change, indicate sensor malfunction. Discrepancies between the APPS and TPS signals can disrupt engine performance. An oscilloscope or scan tool facilitates comprehensive data analysis.

-

Wiring Harness and Connector Integrity Checks

The integrity of the wiring harness and connectors is paramount for signal transmission between components. A visual inspection identifies damaged or corroded wiring, while continuity testing confirms electrical paths. Voltage drop tests under load reveal resistive connections. Faulty wiring or connectors can cause intermittent system malfunctions or complete failures, necessitating replacement or repair of affected components.

These testing procedures are essential for the precise diagnosis of electronic throttle control system issues. By evaluating individual components, technicians can pinpoint the root cause of performance anomalies and implement targeted repairs. Properly executed component testing minimizes guesswork and optimizes maintenance efforts, ensuring the system operates reliably and efficiently.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

4. Wiring Integrity

The electrical wiring system is a critical foundation for the proper functioning of the electronic throttle control system. Its integrity directly influences the accuracy and reliability of signals transmitted between sensors, the ECU, and actuators. Compromised wiring can lead to a multitude of issues, undermining the system’s ability to regulate engine power effectively.

-

Signal Transmission Accuracy

The accuracy of sensor data transmitted to the ECU is paramount. Damaged or degraded wiring introduces resistance, voltage drops, or signal interference. For instance, increased resistance in the throttle position sensor circuit can cause the ECU to receive inaccurate throttle position data, leading to incorrect fuel delivery and compromised engine performance. Such inaccuracies manifest as hesitation, poor idling, or a complete lack of throttle response.

-

Power Supply Stability

The electronic throttle control system requires a stable power supply for reliable operation. Faulty wiring or corroded connections can cause voltage fluctuations, which disrupt the function of the throttle body motor. An unstable power supply may cause the motor to operate erratically, leading to unstable idle conditions and throttle control issues. In extreme cases, insufficient voltage can prevent the motor from operating altogether, triggering a limp-home mode.

-

Grounding Effectiveness

Proper grounding is essential to prevent electrical noise and ensure accurate sensor readings. Inadequate grounding creates ground loops, which interfere with low-voltage signals and introduce spurious data. A faulty ground connection can cause the ECU to misinterpret sensor inputs, resulting in improper engine control and potentially damaging the system. Symptoms include intermittent performance problems and the generation of false diagnostic trouble codes.

-

Connector Reliability

Connectors provide critical junctions for wiring harnesses within the system. Corrosion, loose connections, or damaged connector pins compromise the electrical pathway. A corroded connector on the throttle position sensor can intermittently disconnect the signal, resulting in sudden engine stalling or erratic throttle behavior. Regular inspection and maintenance of connectors are therefore crucial for maintaining system reliability.

The interplay between wiring integrity and electronic throttle control performance necessitates careful attention to detail during maintenance and repair. Ensuring the wiring system is free from damage, corrosion, and loose connections is paramount to maintaining optimal engine control and preventing a range of performance issues. The electronic throttle control system relies on signals that traverse the wire to each component.

5. Fault Codes

Fault codes serve as critical indicators within the electronic throttle control system, signaling deviations from expected operational parameters. These codes, stored within the vehicle’s engine control unit (ECU), provide a starting point for diagnosing malfunctions and guiding repair procedures.

-

Diagnostic Trouble Code (DTC) Generation

The ECU continuously monitors various sensors and actuators within the electronic throttle control system. When a measured value falls outside of pre-defined thresholds, the ECU generates a specific DTC. For example, if the throttle position sensor signal deviates excessively from the accelerator pedal position, a code indicating a TPS/APPS correlation issue is stored. These codes provide technicians with initial information about potential fault locations.

-

Code Interpretation and Troubleshooting

Diagnostic scan tools are used to retrieve stored DTCs from the ECU. Each code corresponds to a specific fault description, providing a starting point for troubleshooting. However, a single code may have multiple potential causes. For instance, a code indicating a throttle actuator control system malfunction could be due to a faulty throttle body motor, wiring issues, or a malfunctioning ECU. Therefore, further investigation is often required to pinpoint the root cause.

-

Common Fault Code Categories

Fault codes within the electronic throttle control system typically fall into several broad categories: sensor-related faults (e.g., TPS, APPS), actuator-related faults (e.g., throttle body motor), circuit faults (e.g., open circuit, short circuit), and performance-related faults (e.g., idle speed control issues). Each category suggests different areas to investigate during the diagnostic process. For instance, a code indicating an open circuit in the throttle actuator control system would prompt an examination of wiring and connectors.

-

Impact on System Operation

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

The presence of fault codes can directly impact the electronic throttle control system’s operation. In some cases, the ECU may enter a limp-home mode, restricting engine power and limiting vehicle speed to prevent further damage. For example, a code indicating a severe throttle position sensor malfunction may trigger limp-home mode to prevent uncontrolled acceleration. Addressing fault codes promptly is essential to restore normal system operation and prevent potential safety hazards.

The presence and interpretation of fault codes are integral to the maintenance and repair of the electronic throttle control system. These codes provide valuable insights into potential malfunctions, guiding technicians through a systematic diagnostic process to identify and rectify underlying issues.

6. Throttle Body

The throttle body is a central component of the electronic throttle control system, directly regulating airflow into the engine. As such, its condition and functionality are intrinsically linked to the overall performance and reliability of the entire system; therefore, any procedure aimed at the “service electronic throttle control” will involve consideration of this part.

-

Mechanical Function and Airflow Regulation

The throttle body houses a throttle plate that pivots to control the amount of air entering the engine’s intake manifold. Precise control over airflow is crucial for proper combustion, fuel efficiency, and engine response. Over time, carbon deposits and contaminants can accumulate on the throttle plate and within the throttle body bore. Such deposits can impede the smooth movement of the plate, disrupting airflow and causing issues such as rough idling, hesitation upon acceleration, and reduced fuel economy. As part of the “service electronic throttle control” the inspection and cleaning of the throttle body will happen.

-

Throttle Position Sensor (TPS) Integration

The throttle position sensor (TPS) is typically mounted directly on the throttle body, providing the engine control unit (ECU) with real-time information about the throttle plate’s position. Accurate TPS readings are essential for the ECU to calculate the correct air-fuel mixture and ignition timing. A malfunctioning TPS, often due to wear or contamination within the throttle body environment, can result in inaccurate readings, leading to various engine performance problems. As part of the “service electronic throttle control” the TPS will be tested, adjusted and potentially replaced.

-

Electronic Actuator and Control

In modern electronic throttle control systems, a motor driven actuator directly controls the throttle plate’s position based on signals from the ECU. This eliminates the mechanical linkage between the accelerator pedal and throttle body. The throttle body’s actuator and the associated electronic circuitry must function reliably. Issues with the actuator can lead to a complete loss of throttle control or erratic throttle plate movements, triggering diagnostic trouble codes (DTCs) and potentially causing the engine to enter a limp-home mode. “Service electronic throttle control” entails testing the actuator’s responsiveness and its ability to maintain the specified throttle position.

-

Cleaning and Maintenance Procedures

Regular cleaning of the throttle body is essential for maintaining optimal engine performance. The removal of carbon deposits and contaminants can restore proper airflow and ensure accurate throttle plate movement. Special throttle body cleaners are typically used to dissolve deposits without damaging sensitive electronic components. Proper cleaning procedures involve disconnecting the battery to prevent accidental throttle plate movement and using a soft brush or cloth to remove debris. “Service electronic throttle control” includes a cleaning stage and a re-calibration to prevent issues.

In summary, the throttle body’s role as a central component directly involved in airflow regulation, sensor integration, electronic control, and required maintenance firmly establishes its connection with the broader aspects of “service electronic throttle control”. Any comprehensive service will focus on the inspection, cleaning, testing and re-calibration of the throttle body.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and repair of electronic throttle control systems, providing concise answers to frequently asked questions.

Question 1: What are the primary indicators that the electronic throttle control system requires service?

Symptoms suggesting a potential issue may include erratic idling, hesitation upon acceleration, reduced engine power, the illumination of the check engine light, or the activation of a limp-home mode.

Question 2: What is the expected lifespan of components within the electronic throttle control system?

Suggested read: Ultimate Guide to Service Marks: Protecting Your Brand Identity

Component lifespan varies depending on driving conditions, maintenance practices, and component quality. However, throttle position sensors and throttle body motors are subject to wear and may require replacement after several years or a significant number of miles.

Question 3: Is it possible to diagnose electronic throttle control issues without specialized equipment?

While a visual inspection for damaged wiring and loose connections is possible, accurate diagnosis typically requires a diagnostic scan tool to retrieve fault codes and monitor sensor data. Component-level testing also necessitates specialized equipment, such as multimeters and oscilloscopes.

Question 4: Can cleaning the throttle body resolve all electronic throttle control-related problems?

Cleaning the throttle body can address issues caused by carbon buildup and contaminants. However, it will not resolve problems caused by faulty sensors, actuators, or wiring. Cleaning is often a necessary part of a comprehensive service, but it is not a guaranteed solution for all problems.

Question 5: What are the potential consequences of neglecting electronic throttle control system maintenance?

Neglecting maintenance can lead to reduced engine performance, decreased fuel efficiency, increased emissions, and potentially dangerous driving conditions. In severe cases, a complete loss of throttle control can occur, posing a significant safety risk.

Question 6: Is professional service always required for electronic throttle control system repairs?

While some basic maintenance tasks, such as visual inspections, can be performed by vehicle owners, most diagnostic and repair procedures require specialized knowledge, equipment, and technical expertise. Engaging a qualified technician is recommended for accurate diagnosis and effective repairs.

In summary, proper maintenance and timely repairs are essential for ensuring the reliable and safe operation of the electronic throttle control system. Addressing potential issues promptly can prevent more serious problems and maintain optimal vehicle performance.

The following section will explore advanced diagnostic and repair techniques for specific electronic throttle control system malfunctions.

Service Electronic Throttle Control

The following recommendations are provided to enhance the efficacy and longevity of electronic throttle control systems, thereby mitigating potential malfunctions and optimizing vehicle performance.

Tip 1: Adhere to Scheduled Maintenance Intervals. Routine inspections and maintenance, as outlined in the vehicle’s service manual, are crucial. This proactive approach enables the early detection of potential issues before they escalate into major failures.

Tip 2: Utilize Genuine or OEM-Equivalent Replacement Parts. When replacement components are necessary, prioritize the use of genuine parts from the original manufacturer or reputable OEM-equivalent alternatives. This ensures compatibility and adherence to stringent quality standards, minimizing the risk of premature failure.

Suggested read: The Essential Guide to Finding a Top-Notch Service Professor

Tip 3: Conduct Thorough Diagnostic Procedures. Prioritize a comprehensive diagnostic evaluation before initiating any repairs. Rely on advanced diagnostic tools and a systematic approach to pinpoint the precise cause of the malfunction, preventing unnecessary component replacements.

Tip 4: Emphasize Wiring Integrity. Pay meticulous attention to the condition of wiring harnesses and connectors. Inspect for signs of corrosion, damage, or loose connections. Address any wiring issues promptly to ensure reliable signal transmission within the system.

Tip 5: Calibrate After Component Replacement. Following the replacement of any sensor or actuator within the system, perform a proper calibration procedure. This ensures that the electronic parameters are accurately aligned with the mechanical components, optimizing system performance.

Tip 6: Address Fault Codes Methodically. When diagnostic trouble codes are present, interpret them accurately and follow the recommended troubleshooting procedures. Avoid simply replacing components based solely on the code; instead, verify the underlying cause of the malfunction.

Tip 7: Maintain Throttle Body Cleanliness. Regularly clean the throttle body to remove carbon deposits and contaminants that can impede airflow and compromise throttle plate movement. Employ approved cleaning solutions and avoid aggressive scrubbing that could damage sensitive components.

Effective implementation of these best practices translates to enhanced reliability, optimized performance, and reduced downtime. Proactive maintenance and meticulous repair procedures contribute to the long-term health of the electronic throttle control system.

The subsequent conclusion will consolidate the key aspects of electronic throttle control system maintenance and highlight the importance of continuous learning and adaptation within this rapidly evolving field.

Conclusion

This exploration of service electronic throttle control has underscored its importance in modern vehicle maintenance. From diagnosis and calibration to component testing and wiring integrity, the meticulous upkeep of this system ensures optimal engine performance, fuel efficiency, and safety. The significance of accurate fault code interpretation and proactive throttle body maintenance has also been emphasized.

As automotive technology advances, the complexities of electronic throttle control systems will undoubtedly increase. Therefore, a commitment to continuous learning and adaptation is essential for those involved in vehicle maintenance and repair. Proper understanding and skilled execution of service electronic throttle control procedures are not merely best practices, but rather necessities for ensuring the reliability and longevity of modern vehicles.