This offering constitutes a specialized provision focused on maintaining and improving indoor air quality through the application of advanced filtration and ventilation technologies. It typically involves a comprehensive assessment of existing HVAC systems, followed by the implementation of tailored solutions designed to remove pollutants, allergens, and other harmful particles from the air. An example might include the installation of high-efficiency particulate air (HEPA) filters in conjunction with routine duct cleaning and system optimization.

The significance of this type of provision lies in its contribution to healthier indoor environments, which can lead to improved respiratory health, reduced allergy symptoms, and increased overall well-being for building occupants. Historically, concerns about indoor air quality have grown alongside increasing urbanization and the construction of more tightly sealed buildings, highlighting the need for effective and proactive air purification strategies. These strategies are beneficial in residential, commercial, and industrial settings, particularly where vulnerable populations or sensitive manufacturing processes are involved.

The following sections will delve into specific methodologies employed, potential applications across diverse sectors, and the overall impact on environmental quality and human health. This exploration will offer a clearer understanding of the multifaceted aspects involved in delivering enhanced air quality management.

1. Assessment

The initial evaluation is a foundational stage in the provision of targeted air quality management. Its role is to establish a baseline understanding of existing conditions, identify potential problem areas, and inform the development of a customized remediation strategy. Without a comprehensive assessment, subsequent interventions may be misdirected, inefficient, or even counterproductive.

-

Initial Site Survey

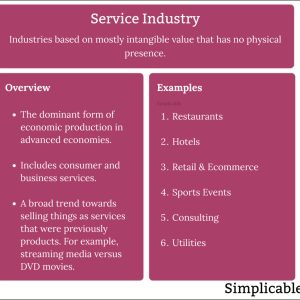

Suggested read: Comprehensive Guide to the Service Industry Definition

This involves a physical inspection of the property, including HVAC systems, ventilation pathways, and potential sources of indoor air pollutants. For example, visible mold growth, dust accumulation in ductwork, or the presence of volatile organic compounds (VOCs) from building materials would be documented. This provides a tangible understanding of the building’s physical state in relation to air quality.

-

Air Quality Testing

Air sampling and analysis are conducted to quantify the levels of various pollutants, such as particulate matter (PM2.5, PM10), allergens, mold spores, and chemical contaminants. For instance, a sample might reveal elevated levels of formaldehyde due to off-gassing from new furniture. The results provide objective data to support observations made during the site survey and identify pollutants that may not be immediately apparent.

-

HVAC System Evaluation

This entails a detailed examination of the heating, ventilation, and air conditioning (HVAC) system’s performance, efficiency, and maintenance history. An inefficient or poorly maintained system can contribute significantly to indoor air quality problems. For example, leaky ductwork can draw in pollutants from crawl spaces or attics, while inadequate filtration can allow contaminants to circulate throughout the building.

-

Occupant Interviews and Health History

Gathering information from building occupants about their health symptoms, sensitivities, and concerns can provide valuable insights into the potential impact of indoor air quality on their well-being. For example, reports of frequent headaches, respiratory irritation, or allergy flare-ups may indicate the presence of specific pollutants or inadequate ventilation.

By synthesizing the data gathered from these assessment components, a clear picture of the building’s air quality profile emerges. This, in turn, enables the formulation of targeted interventions designed to address specific issues, optimize system performance, and improve the overall health and comfort of building occupants. The assessment is not merely a preliminary step but an ongoing process of monitoring and evaluation to ensure sustained air quality improvement.

2. Maintenance Procedures

Systematic upkeep forms an integral component of ensuring effective and consistent operation. Scheduled servicing, cleaning, and component replacement are essential to preventing the degradation of air quality over time. A neglected system, regardless of its initial design or filtration capabilities, will invariably experience a decline in performance, leading to the reintroduction of pollutants into the indoor environment. Consider, for instance, a hospital operating room where stringent air purity is paramount; failure to adhere to scheduled filter replacements and duct cleaning protocols can increase the risk of airborne infection transmission, potentially compromising patient health and safety. Therefore, scheduled maintenance is not merely a supplementary activity but a critical, recurring requirement.

The specific procedures involved vary depending on the type of system, the building’s occupancy, and the surrounding environmental conditions. These procedures encompass several key areas, including filter replacement, coil cleaning, ductwork inspection and sanitation, and system component lubrication and calibration. For example, in a manufacturing facility producing sensitive electronic components, the maintenance schedule might include more frequent filter changes and specialized duct cleaning methods to minimize the risk of particulate contamination that could damage the products. Furthermore, predictive maintenance techniques, such as vibration analysis of fan motors, can identify potential issues before they escalate into significant problems, preventing costly downtime and maintaining consistent air quality.

In conclusion, the efficacy of any air quality management relies significantly on diligent and well-executed maintenance procedures. These procedures are not isolated events but rather a continuous process of monitoring, servicing, and optimizing system performance. Regular and thorough maintenance not only extends the lifespan of equipment but also ensures that the intended benefits of cleaner, healthier indoor air are consistently realized, safeguarding occupants and preserving operational integrity.

3. Filtration Technology

Filtration technology forms a cornerstone of the offered service. The capacity to remove airborne particulates, allergens, and other contaminants directly determines the effectiveness of any air quality intervention. Inferior filtration results in the continued circulation of pollutants, negating the potential benefits of other system components. For instance, in a pharmaceutical manufacturing environment, high-efficiency particulate air (HEPA) filters are essential for removing microorganisms and preventing contamination of sterile products. The selection and proper implementation of appropriate filtration technologies are, therefore, intrinsically linked to the successful delivery of enhanced air quality.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

The variety of filtration technologies available necessitates a tailored approach to their selection and application. Options range from basic mechanical filters designed to capture larger particles like dust and pollen, to advanced electronic filters that utilize ionization or electrostatic attraction to remove even the smallest sub-micron particles. Furthermore, activated carbon filters are frequently employed to adsorb volatile organic compounds (VOCs) and odors, while ultraviolet (UV) light systems can be integrated to neutralize airborne pathogens. For example, a hospital might utilize a combination of HEPA filters and UV-C irradiation in its ventilation system to minimize the risk of hospital-acquired infections. The practical application relies on a careful assessment of the specific contaminants present and the required level of air purity.

In summation, filtration technology is not simply an adjunct to the provided service but rather a critical component that dictates its overall performance and utility. The judicious selection, proper installation, and consistent maintenance of appropriate filtration systems are essential for achieving and sustaining desired air quality outcomes. Challenges arise in matching technology to specific needs and ensuring ongoing system integrity; however, effective management hinges on a comprehensive understanding of these technological foundations.

4. Trained Technicians

The effectiveness of any air quality management is inextricably linked to the competence and expertise of the personnel responsible for its implementation and maintenance. Untrained or inadequately trained technicians present a direct threat to the integrity of the systems, potentially compromising their performance and negating their intended benefits. The proper assessment, installation, calibration, and troubleshooting of advanced filtration and ventilation systems require a comprehensive understanding of engineering principles, HVAC system mechanics, and indoor air quality science. For example, an improperly installed HEPA filter can create air bypasses, allowing unfiltered air to circulate and rendering the filter largely ineffective. Similarly, incorrect calibration of airflow dampers can disrupt ventilation patterns, leading to stagnant air pockets and localized pollutant accumulation.

The role of qualified technicians extends beyond mere mechanical tasks to encompass diagnostic capabilities and problem-solving skills. They must be capable of identifying the root causes of air quality issues, evaluating the performance of existing systems, and recommending appropriate solutions. Consider, for instance, a scenario in which occupants of a building are experiencing recurring respiratory symptoms despite the presence of a seemingly adequate ventilation system. A trained technician would be able to conduct a thorough investigation, which might reveal issues such as hidden mold growth in ductwork, inadequate filtration levels, or improper system settings. Their expertise allows for the implementation of targeted interventions that address the specific problems, rather than relying on generic or ineffective measures. The value of this specialized knowledge underscores the importance of certified and experienced professionals.

In conclusion, skilled technicians are indispensable for the successful delivery of enhanced air quality management. Their training and expertise translate directly into improved system performance, accurate diagnostics, and effective remediation strategies. Investments in technician training and certification are, therefore, essential for safeguarding the health and well-being of building occupants and ensuring the long-term effectiveness of air quality interventions. The failure to prioritize the human element in air quality management represents a critical oversight, potentially undermining the entire endeavor.

5. Quality Assurance

Quality assurance (QA) is inextricably linked to the delivery and sustained efficacy of specialized air quality management. It serves as the systematic process by which the provided service is consistently evaluated against pre-defined standards and performance metrics. The absence of a robust QA framework can result in inconsistent performance, undetected system failures, and ultimately, a failure to achieve the desired improvements in indoor air quality. For instance, without regular inspections and testing, filter bypasses may go unnoticed, allowing unfiltered air to circulate and compromising the entire filtration system’s effectiveness. QA, therefore, acts as a critical control mechanism, ensuring adherence to established protocols and optimizing system performance.

The implementation of QA within the described service encompasses various stages, from initial system design and installation to ongoing maintenance and monitoring. At the design stage, QA involves verifying that the selected equipment and system configuration meet the specific needs of the environment, considering factors such as pollutant levels, ventilation requirements, and building occupancy. During installation, QA ensures that all components are properly installed and calibrated, adhering to manufacturer specifications and industry best practices. Ongoing QA activities include regular system inspections, air quality testing, filter performance monitoring, and customer feedback analysis. For example, routine air sampling can detect elevated levels of particulate matter, prompting corrective actions such as filter replacement or duct cleaning. These activities allow for the early detection and resolution of potential issues, preventing them from escalating into more significant problems and maintaining consistent air quality over time.

In conclusion, quality assurance is not merely a supplementary aspect but an essential, integral component of the service. It provides the framework for ensuring consistent performance, identifying and addressing potential issues, and ultimately, delivering the intended improvements in indoor air quality. The benefits of a robust QA program extend beyond mere compliance with standards, leading to increased customer satisfaction, reduced operational costs, and improved health and well-being for building occupants. The sustained efficacy relies on a commitment to continuous improvement and a rigorous adherence to established protocols.

Frequently Asked Questions

This section addresses common inquiries regarding this offering, providing detailed information to clarify its scope, benefits, and operational aspects.

Question 1: What defines the scope of the air quality management provided?

The scope encompasses a comprehensive assessment of existing HVAC systems and indoor air quality, followed by the implementation of tailored solutions. These solutions may include enhanced filtration, duct cleaning, system optimization, and the monitoring of air quality parameters. The specific services provided are determined by the unique needs of each environment.

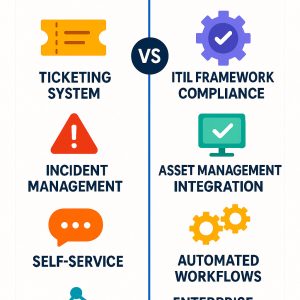

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

Question 2: What are the primary benefits derived from improved indoor air quality?

Improved indoor air quality can lead to several benefits, including reduced respiratory symptoms, allergy flare-ups, and the risk of airborne infections. Additionally, it can enhance cognitive function, productivity, and overall well-being for building occupants. In certain industrial settings, improved air quality can also protect sensitive manufacturing processes from contamination.

Question 3: How frequently should air quality systems undergo maintenance?

The recommended maintenance frequency depends on several factors, including the type of system, the building’s occupancy, and the surrounding environmental conditions. Generally, systems should be inspected and serviced at least annually, with more frequent maintenance required in environments with high levels of pollutants or sensitive operations.

Question 4: What filtration technologies are commonly utilized?

A range of filtration technologies may be employed, including mechanical filters, HEPA filters, activated carbon filters, and ultraviolet (UV) light systems. The selection of appropriate filtration technologies depends on the specific contaminants present and the required level of air purity. A comprehensive assessment is conducted to determine the most suitable technologies for each application.

Question 5: What qualifications do the technicians possess?

Technicians possess relevant certifications and undergo rigorous training to ensure competence in HVAC systems, air quality science, and safety protocols. They are equipped to perform system assessments, installations, maintenance, and repairs, adhering to industry best practices and regulatory requirements.

Suggested read: Ultimate Guide to Service Marks: Protecting Your Brand Identity

Question 6: How is the effectiveness of the air quality management system measured?

The effectiveness is measured through a combination of methods, including air quality testing, system performance monitoring, and occupant feedback. Air quality testing provides objective data on pollutant levels, while system performance monitoring tracks the efficiency and effectiveness of the HVAC system. Occupant feedback offers valuable insights into the perceived improvements in indoor air quality and overall comfort.

In summary, effective air quality management requires a holistic approach, encompassing comprehensive assessments, tailored solutions, skilled technicians, and ongoing quality assurance. By addressing these key elements, it is possible to create healthier, more comfortable, and more productive indoor environments.

The following sections will further examine specific case studies and technological advancements in the field.

Expert Guidance

The following insights are intended to assist in maintaining and optimizing indoor environmental conditions. These tips address key areas relevant to achieving and sustaining superior air quality.

Tip 1: Prioritize Regular Filter Replacements: Adherence to recommended filter replacement schedules is critical. Clogged filters impede airflow, reduce system efficiency, and diminish the capacity to remove airborne particulates. Consult manufacturer specifications for appropriate filter types and replacement intervals.

Tip 2: Ensure Proper Ventilation: Adequate ventilation is essential for diluting indoor pollutants and introducing fresh air. Verify that ventilation systems are functioning optimally and that air intakes are free from obstructions. Consider increasing ventilation rates during periods of high occupancy or pollutant generation.

Tip 3: Maintain Cleanliness: Regular cleaning of indoor surfaces, including floors, carpets, and furniture, helps to reduce the accumulation of dust, allergens, and other pollutants. Utilize appropriate cleaning methods and materials to minimize the release of volatile organic compounds (VOCs).

Tip 4: Control Humidity Levels: Maintaining appropriate humidity levels is important for preventing mold growth and reducing the survival of certain airborne pathogens. Aim for humidity levels between 30% and 50%. Use dehumidifiers or humidifiers as needed to regulate humidity levels.

Tip 5: Address Sources of Pollution: Identify and mitigate sources of indoor pollution, such as tobacco smoke, gas stoves, and certain cleaning products. Opt for low-VOC paints, sealants, and adhesives. Ensure proper ventilation when using products that release pollutants.

Tip 6: Schedule Routine HVAC System Inspections: Regular inspections by qualified technicians can identify potential issues, such as duct leaks, coil contamination, and malfunctioning components. Addressing these issues promptly can prevent significant air quality problems and extend the lifespan of the HVAC system.

Suggested read: The Essential Guide to Finding a Top-Notch Service Professor

Tip 7: Monitor Air Quality: Employ air quality monitoring devices to track pollutant levels and identify potential problems. These devices can provide valuable data for assessing the effectiveness of air quality management strategies and making informed decisions.

Consistent application of these guidelines can significantly contribute to a healthier and more comfortable indoor environment. Prioritizing these areas promotes enhanced air quality and overall well-being.

The subsequent sections will delve into specific case studies and technological advancements that are pertinent to enhancing indoor air environments.

In Conclusion

The preceding analysis has explored the multifaceted nature of certus airvac service, examining its critical components, operational dimensions, and associated benefits. Emphasis has been placed on the significance of thorough assessments, rigorous maintenance procedures, appropriate filtration technologies, trained technicians, and consistent quality assurance. These elements collectively contribute to the provision of enhanced indoor air quality and the safeguarding of occupant health.

The ongoing commitment to effective air quality management is paramount. Continued vigilance in system maintenance, adoption of technological advancements, and adherence to established protocols are essential for sustaining optimal indoor environmental conditions. The pursuit of improved air quality represents a responsible investment in the well-being of individuals and the overall functionality of buildings.