Automotive electrical systems are essential for a vehicle’s operation, encompassing components like the battery, starter, alternator, and wiring harness. Maintenance and repair of these systems ensure the reliable function of critical vehicle features such as starting, charging, lighting, and electronic controls. Diagnosing a non-starting condition, for example, often involves evaluating the battery’s health and the functionality of the starter motor and related circuits.

The proper functioning of a vehicle’s electrical network directly impacts its overall performance, safety, and longevity. A well-maintained electrical system improves fuel efficiency by ensuring the alternator operates optimally, provides dependable lighting for nighttime driving, and supports the increasing array of electronic devices in modern vehicles. Historically, rudimentary electrical systems were limited to basic lighting and starting functions. Over time, advancements have led to complex, interconnected networks controlling nearly every aspect of a vehicle’s operation.

Therefore, understanding the fundamentals of automotive electrical systems is crucial for vehicle owners and technicians alike. The following sections will delve into specific aspects, including common electrical problems, diagnostic techniques, and preventative maintenance strategies to ensure optimal vehicle performance and reliability.

1. Diagnosis

Effective diagnosis forms the cornerstone of reliable automotive electrical maintenance. Accurate identification of electrical faults is paramount to efficient repair and the prevention of further system damage.

-

Symptom Identification

The diagnostic process begins with a thorough assessment of vehicle symptoms. Dim headlights, a non-starting engine, or erratic operation of electronic accessories indicate potential electrical issues. For example, a driver reporting that their power windows operate intermittently under certain conditions provides crucial data for the technician to initiate targeted testing.

-

Circuit Testing

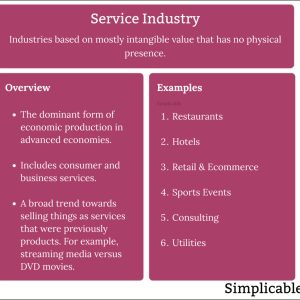

Suggested read: Comprehensive Guide to the Service Industry Definition

Utilizing specialized tools such as multimeters, oscilloscopes, and circuit testers, technicians systematically evaluate the integrity of electrical circuits. Voltage, current, and resistance measurements reveal open circuits, shorts, and excessive resistance, pinpointing the location of the fault. A voltage drop test, for instance, identifies areas of high resistance in a circuit, often caused by corrosion or loose connections.

-

Module Scanning

Modern vehicles incorporate numerous electronic control units (ECUs) that manage various systems. Diagnostic scanners interface with these ECUs to retrieve stored diagnostic trouble codes (DTCs). These codes provide valuable information regarding specific electrical malfunctions, narrowing down the scope of the diagnostic investigation. A DTC indicating a faulty oxygen sensor heater circuit, for example, directs the technician to inspect the heater circuit wiring and the sensor itself.

-

Component Testing

Individual electrical components, such as alternators, starters, and sensors, require individual testing to verify their functionality. Specialized testing procedures determine whether a component is operating within its specified parameters. A load test of the battery, for example, assesses its ability to provide sufficient current under load, revealing its state of health and ability to support the vehicle’s electrical demands.

These diagnostic facets are integral to providing effective automotive electrical maintenance. The accurate and efficient application of these processes leads to timely repairs, reduced vehicle downtime, and ensures the continued reliable operation of the vehicle’s electrical systems.

2. Repair

Electrical system repair is a critical aspect of automotive maintenance, addressing malfunctions that compromise vehicle functionality and safety. Repair procedures aim to restore electrical systems to their intended operational state, ensuring reliable performance and preventing further damage.

-

Wiring Harness Repair

Damage to wiring harnesses, resulting from physical stress, environmental exposure, or rodent activity, necessitates careful repair. This involves identifying damaged wires, replacing sections where necessary, and ensuring proper insulation and protection. For example, a frayed wire causing intermittent headlight function requires splicing in a new wire section and sealing the connection to prevent future corrosion. This type of repair directly restores circuit continuity and prevents short circuits that could damage other components.

-

Component Replacement

When electrical components such as alternators, starters, or sensors fail, replacement with functioning parts is required. Proper selection of replacement components is crucial to ensure compatibility and performance. A faulty alternator, for instance, must be replaced with one that matches the vehicle’s electrical system specifications to provide adequate charging voltage and current. Incorrect component selection can lead to system damage or suboptimal performance.

-

Connector and Terminal Repair

Corrosion and damage to electrical connectors and terminals can disrupt circuit continuity and cause intermittent malfunctions. Repair involves cleaning corroded terminals, replacing damaged connectors, and ensuring secure connections. For example, cleaning corroded battery terminals ensures proper current flow to the starter motor. Neglecting this can result in a no-start condition. Proper repair of these connections is crucial for maintaining reliable electrical function.

-

Circuit Troubleshooting and Correction

Identifying the root cause of circuit malfunctions often requires extensive troubleshooting using diagnostic tools and wiring diagrams. Once the cause is identified, corrective action is implemented. For example, locating and repairing a short circuit in a lighting system involves tracing the wiring, identifying the point of contact, and isolating it to prevent recurrence. This ensures that the circuit operates as intended, preventing damage to other components and enhancing vehicle safety.

These repair facets underscore the importance of skilled technicians and proper diagnostic procedures in maintaining the electrical integrity of a vehicle. Thorough and accurate repairs ensure reliable vehicle operation and minimize the risk of future electrical malfunctions.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

3. Maintenance

Preventive maintenance of automotive electrical systems is essential to ensuring vehicle reliability, safety, and longevity. Consistent maintenance practices mitigate potential electrical failures, optimize system performance, and reduce the likelihood of costly repairs.

-

Battery Maintenance

Regular battery maintenance encompasses several key procedures, including terminal cleaning, electrolyte level checks (for conventional batteries), and voltage testing. Corrosion on battery terminals impedes current flow, potentially leading to starting difficulties or charging system inefficiencies. Maintaining proper electrolyte levels ensures optimal battery performance and lifespan. Voltage testing assesses the battery’s state of charge and its ability to hold a charge, identifying potential weaknesses or impending failures. For instance, a battery consistently exhibiting low voltage may indicate the need for replacement, preventing a no-start situation during critical times.

-

Wiring Inspection

Periodic inspection of wiring harnesses and connectors is crucial to identify signs of damage, corrosion, or wear. Damaged insulation exposes wires to environmental elements, increasing the risk of short circuits and electrical malfunctions. Loose connectors create resistance, hindering proper current flow and potentially causing intermittent system failures. A visual inspection can reveal frayed wires rubbing against the vehicle’s chassis or corroded connectors exposed to moisture. Addressing these issues promptly prevents further damage and ensures reliable circuit operation.

-

Charging System Evaluation

Evaluating the charging system involves assessing the alternator’s output voltage and current under varying engine loads. An underperforming alternator fails to adequately recharge the battery, leading to gradual battery depletion and potential starting problems. Overcharging, conversely, damages the battery and other electrical components. Monitoring the charging system’s performance ensures the battery receives the appropriate charge voltage and current, prolonging its lifespan and preventing electrical system failures. Regular testing can identify an alternator nearing the end of its service life, allowing for proactive replacement.

-

Lighting System Check

Regular inspection of the lighting system, including headlights, taillights, brake lights, and turn signals, is vital for safety. Burned-out bulbs compromise visibility and increase the risk of accidents. Faded or damaged lenses reduce light output, diminishing nighttime visibility. Checking and replacing bulbs and lenses as needed ensures optimal lighting performance, contributing to safer driving conditions. Verification of proper operation of all lights during routine maintenance is a crucial safety measure.

These maintenance practices, when consistently applied, significantly enhance the reliability and performance of automotive electrical systems. Proactive maintenance not only prevents electrical failures but also prolongs the lifespan of electrical components, ultimately reducing vehicle operating costs and ensuring safer driving conditions.

4. Component Replacement

Component replacement is an integral aspect of automotive electrical maintenance, representing a direct response to diagnosed failures within a vehicle’s electrical system. The necessity for component replacement arises from various factors, including wear and tear, corrosion, or damage resulting from electrical overloads or physical trauma. For example, the failure of an alternator, crucial for maintaining battery charge and powering electrical accessories, necessitates replacement to restore proper vehicle operation. Similarly, a malfunctioning starter motor, responsible for initiating engine combustion, requires replacement to enable the vehicle to start. These examples illustrate the cause-and-effect relationship between component failure and the need for replacement to rectify the underlying electrical issue.

The efficacy of component replacement hinges on accurate diagnosis and the selection of compatible, high-quality replacement parts. A misdiagnosis leading to the replacement of a functioning component represents wasted resources and a failure to address the actual problem. The selection of subpar replacement parts compromises the vehicle’s electrical system’s long-term reliability and performance. Consider the case of a faulty sensor within the engine management system. Replacement with a low-quality sensor can result in inaccurate readings, leading to reduced fuel efficiency, increased emissions, and potential engine damage. The strategic use of Original Equipment Manufacturer (OEM) parts or reputable aftermarket alternatives helps ensure the replacement component meets the vehicle’s specific electrical requirements.

The successful execution of component replacement within automotive electrical systems ultimately contributes to enhanced vehicle reliability, improved safety, and extended vehicle lifespan. By addressing electrical failures through strategic component replacements, vehicles can maintain their intended operational capabilities and minimize the risk of further system damage. Component replacement is essential to automotive electrical maintenance, serving as a reactive measure to restore electrical system functionality and ensure safe vehicle operation.

5. System Upgrades

System upgrades within the realm of automotive electric service represent enhancements or additions to a vehicle’s existing electrical infrastructure. These modifications serve to improve performance, add functionality, or enhance safety. The integration of aftermarket electronic devices or improvements to existing electrical systems necessitates careful planning and execution to ensure compatibility and reliability.

-

Enhanced Lighting Systems

Upgrading to higher-intensity headlights, such as LED or HID systems, enhances visibility, improving safety during nighttime driving. The implementation of these systems requires proper wiring and installation to ensure compliance with safety standards and prevent electrical overloads. For example, adding LED fog lights can improve visibility in inclement weather, but the installation must adhere to the vehicle’s electrical specifications to avoid damaging the electrical system.

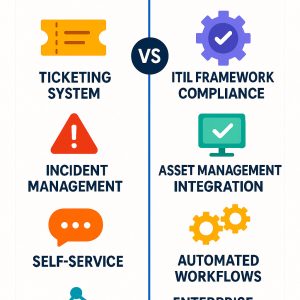

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

-

Advanced Audio Systems

Installing aftermarket audio systems, including amplifiers, subwoofers, and advanced head units, elevates the in-vehicle entertainment experience. These systems often require additional power and wiring, potentially necessitating upgrades to the vehicle’s charging system. High-powered audio systems draw significant current, placing a strain on the battery and alternator; professional installation ensures adequate power delivery and prevents electrical damage.

-

Security Systems and Remote Starters

Integrating advanced security systems and remote starters enhances vehicle security and convenience. These systems require interfacing with the vehicle’s electrical system, including the ignition, door locks, and alarm system. Improper installation can lead to electrical malfunctions or compromise the vehicle’s security. For example, installing a remote starter incorrectly can disable the anti-theft system or cause the vehicle to start unexpectedly.

-

Charging Ports and Power Inverters

Adding USB charging ports or power inverters expands the vehicle’s utility, allowing occupants to charge electronic devices or power appliances. These additions require careful wiring and integration into the vehicle’s electrical system. Overloading the system with excessive power demands can damage the wiring or cause a system failure. Installing a power inverter to run a laptop, for example, requires ensuring that the vehicle’s electrical system can handle the additional load without causing damage.

These system upgrades, while offering enhanced functionality and convenience, require expert knowledge and precise execution within the context of automotive electric service. Ensuring compatibility, proper installation, and adherence to safety standards is paramount in maintaining the reliability and integrity of the vehicle’s electrical system.

Frequently Asked Questions About Auto Electric Service

This section addresses common inquiries concerning automotive electrical system maintenance, repair, and diagnosis. The information provided aims to clarify technical aspects and offer guidance on ensuring optimal vehicle electrical performance.

Question 1: What are the primary indicators of a malfunctioning automotive electrical system?

Common symptoms include a non-starting engine, dim or flickering lights, a continuously dead battery, erratic operation of electronic accessories (e.g., power windows, radio), and warning lights illuminating on the dashboard. Identifying these symptoms early is crucial for preventing more significant electrical damage.

Question 2: How frequently should a vehicle’s electrical system undergo inspection and maintenance?

A thorough electrical system inspection is advisable at least annually, or more frequently if the vehicle experiences any electrical-related issues. Regular maintenance, such as battery terminal cleaning and visual inspection of wiring, helps prevent future problems.

Question 3: What diagnostic tools are typically employed in automotive electrical service?

Suggested read: Ultimate Guide to Service Marks: Protecting Your Brand Identity

Technicians utilize a range of specialized tools, including multimeters (for measuring voltage, current, and resistance), oscilloscopes (for analyzing electrical signals), diagnostic scanners (for retrieving diagnostic trouble codes), and circuit testers (for verifying circuit continuity and integrity).

Question 4: What is a parasitic draw, and how is it diagnosed?

A parasitic draw refers to an excessive current drain from the battery when the vehicle is turned off. This can lead to battery depletion and starting problems. Diagnosis involves measuring the current draw from the battery with the engine off and systematically disconnecting circuits to identify the source of the excessive drain.

Question 5: Is it possible to upgrade a vehicle’s electrical system, and what are the benefits?

Upgrading a vehicle’s electrical system is feasible and can offer several benefits, including improved lighting performance (e.g., LED headlights), enhanced audio system capabilities, and the ability to power aftermarket accessories. However, upgrades must be performed by qualified technicians to ensure compatibility and prevent system damage.

Question 6: How does battery maintenance affect the lifespan of an automotive battery?

Proper battery maintenance, including terminal cleaning, electrolyte level checks (if applicable), and regular voltage testing, significantly extends battery lifespan. Neglecting these practices can lead to premature battery failure and necessitate costly replacements.

These FAQs provide a basic understanding of common aspects related to auto electric service. Consulting with a qualified automotive technician remains essential for accurate diagnosis and reliable repair.

This concludes the FAQ section. Subsequent sections will delve into specific electrical service procedures in greater detail.

Auto Electric Service

Maintaining a vehicle’s electrical system is paramount for reliable operation and safety. Adhering to the following guidelines can significantly extend the lifespan of electrical components and prevent unexpected failures.

Tip 1: Regularly Inspect Battery Terminals: Corrosion on battery terminals impedes current flow, leading to starting problems. Clean terminals with a wire brush and apply a corrosion-inhibiting compound to ensure optimal conductivity. Neglecting this simple task can result in a no-start condition and premature battery failure.

Tip 2: Monitor Battery Voltage: A battery’s state of charge indicates its health. Use a multimeter to periodically check the battery voltage. A fully charged battery should read approximately 12.6 volts. Consistently low voltage suggests a charging system issue or a failing battery requiring attention.

Tip 3: Examine Wiring Harnesses for Damage: Wiring harnesses are susceptible to damage from heat, vibration, and environmental factors. Inspect wiring for frayed insulation, cracks, or loose connections. Address any damage promptly to prevent short circuits and electrical malfunctions. Rodent damage is a common cause of wiring harness issues.

Suggested read: The Essential Guide to Finding a Top-Notch Service Professor

Tip 4: Address Warning Lights Immediately: Dashboard warning lights indicate potential electrical or mechanical problems. Ignoring these warnings can lead to more severe and costly repairs. Consult a qualified technician to diagnose the cause of the warning light and take appropriate action.

Tip 5: Avoid Overloading Electrical Circuits: Connecting excessive electrical devices to a vehicle’s circuits can overload the system and cause damage. Be mindful of the power demands of aftermarket accessories, such as high-powered audio systems or auxiliary lighting. Use appropriately sized fuses and relays to protect circuits from overloads.

Tip 6: Seek Professional Assistance for Complex Issues: Automotive electrical systems are complex. Attempting repairs without proper knowledge and tools can lead to further damage or personal injury. Consult a qualified automotive technician for diagnosis and repair of complex electrical problems.

Tip 7: Maintain a Clean Engine Compartment: A clean engine compartment helps prevent corrosion and damage to electrical components. Regularly clean the engine bay to remove dirt, grease, and debris that can accelerate corrosion. Pay particular attention to electrical connectors and wiring.

These tips provide a foundation for maintaining a healthy automotive electrical system. Consistent attention to these details can prevent unexpected breakdowns and ensure reliable vehicle operation.

The following section will summarize the key takeaways from this article.

Conclusion

This exploration of auto electric service has underscored its critical role in maintaining vehicle reliability, safety, and performance. Key aspects encompass accurate diagnosis, skilled repair, diligent maintenance, strategic component replacement, and judicious system upgrades. Neglecting these facets can lead to diminished vehicle functionality, increased safety risks, and potentially costly repairs.

Prioritizing proactive engagement with qualified auto electric service professionals is essential for ensuring the continued operational integrity of any vehicle. Regular attention to electrical system health translates directly into enhanced vehicle lifespan, improved safety, and optimized performance, benefiting both vehicle owners and the broader transportation ecosystem.