A specialized plumbing fixture, generally found in utility rooms, garages, or commercial settings, provides a dedicated space for tasks involving dirty water disposal and cleaning. Often deeper and more durable than standard sinks, it facilitates activities such as rinsing mops, washing paintbrushes, or handling other messy projects. For example, a custodian might use this fixture to empty a mop bucket after cleaning floors.

The significance of such a fixture lies in its practicality and protective qualities. It prevents contamination of sinks used for food preparation or personal hygiene. Its robust construction and strategically planned location simplify cleanup and maintenance. Historically, these fixtures have been essential in maintaining sanitation and order in both residential and commercial environments, evolving from simple basins to more sophisticated designs with features like integrated drainboards and spray attachments.

With a foundational understanding established, subsequent discussions will delve into various aspects of these fixtures. This will include selection criteria, installation considerations, maintenance procedures, and relevant regulatory compliance measures, thereby providing a complete resource on the subject.

1. Material Durability

Material durability is a critical factor in the longevity and performance of a plumbing fixture designed for heavy-duty use. The demands placed upon such a fixture, including exposure to harsh chemicals, abrasive materials, and significant physical impact, necessitate robust construction. The choice of material directly impacts the fixture’s resistance to corrosion, cracking, and general wear and tear. For instance, a stainless steel fixture, widely recognized for its durability and resistance to corrosion, is often preferred in commercial settings where frequent exposure to cleaning agents is expected. Conversely, a lower-grade plastic fixture may quickly degrade under similar conditions, leading to premature failure and the need for replacement.

The consequences of inadequate material durability extend beyond mere replacement costs. A failure can lead to water damage, disruption of operations, and potential safety hazards. Consider a scenario in a hospital setting where a polypropylene fixture cracks due to repeated use and exposure to disinfectants. The resulting leak could compromise sanitation standards and necessitate costly repairs, diverting resources from essential patient care activities. Similarly, in an industrial environment, a fixture constructed from insufficiently durable material may succumb to the corrosive effects of chemical runoff, leading to contamination of wastewater and potential environmental violations. Therefore, selecting a fixture constructed from appropriate materials is crucial for ensuring long-term reliability and minimizing operational risks.

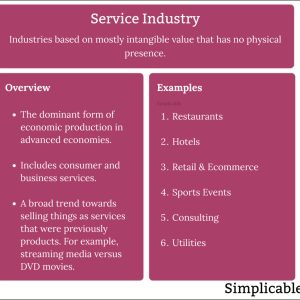

Suggested read: Comprehensive Guide to the Service Industry Definition

In summary, material durability directly dictates the lifespan and overall cost-effectiveness. The ability to withstand the specific challenges posed by its intended environment is paramount. Understanding the relationship between material properties and application requirements is essential for informed selection, promoting efficient operations, and mitigating potential risks associated with premature failure.

2. Capacity Requirements

The capacity requirements of a utility fixture are intrinsically linked to its intended function and the volume of materials it is expected to handle. Proper assessment of these requirements is essential for selecting a fixture that effectively meets the needs of the application, prevents operational inefficiencies, and minimizes the risk of spills or overflows.

-

Frequency of Use and Volume of Materials

The anticipated frequency of use and the typical volume of liquids or materials processed in each use-case directly influence capacity needs. A high-traffic commercial facility, such as a restaurant kitchen, will necessitate a fixture with a greater capacity than a residential garage, where usage is infrequent. For example, a restaurant may require a large-capacity sink to accommodate the disposal of large quantities of water used for cleaning equipment and floors, while a residential user may only need a smaller fixture for occasional tasks.

-

Size and Type of Items to be Cleaned

The size and nature of items intended for cleaning also impact the required capacity. If the fixture is to be used for rinsing large mops, buckets, or equipment components, a deep and wide basin is necessary to accommodate these items comfortably. Conversely, if it is primarily intended for smaller tasks, such as washing paintbrushes or small tools, a smaller basin may suffice. The inability to adequately fit items within the sink can lead to inefficient cleaning practices and potential spills.

-

Disposal of Hazardous Materials

If the fixture is intended for disposing of liquids containing potentially hazardous materials, such as paint thinners or chemical solutions, the capacity must be sufficient to contain the anticipated volume without risking overflow or splashing. Furthermore, considerations for secondary containment and appropriate drainage systems are crucial in such scenarios to prevent environmental contamination. For example, an industrial facility may require a specialized fixture with a large capacity and a sealed drain to handle the disposal of chemical waste.

-

Impact on Water Consumption and Drainage

Larger capacity fixtures inherently require greater water consumption for filling and rinsing. This can impact water bills and strain municipal water resources. Additionally, the increased volume of wastewater generated can place a greater demand on the building’s drainage system. Proper planning and the selection of water-efficient fixtures are essential to mitigate these effects. For instance, incorporating flow restrictors or spray nozzles can help reduce water consumption without compromising cleaning effectiveness.

In conclusion, accurately assessing capacity needs is critical for optimizing the performance and efficiency of a plumbing fixture. Overlooking these requirements can result in operational inefficiencies, increased costs, and potential safety or environmental hazards. Careful consideration of usage patterns, item sizes, and disposal requirements is necessary to ensure the appropriate fixture is selected for the intended application.

3. Drainage Efficiency

Drainage efficiency is paramount in the functionality of any utility fixture, directly impacting its usability, hygiene, and long-term maintenance requirements. Inadequate drainage can lead to standing water, promoting bacterial growth, unpleasant odors, and potential slip hazards. Therefore, the design and implementation of an efficient drainage system are critical considerations in the selection and installation of such a fixture.

-

Slope and Drain Placement

The slope of the basin floor and the strategic placement of the drain significantly affect the rate at which water is evacuated. An insufficient slope can result in water pooling, particularly in corners or low spots, hindering complete drainage. The drain should be located at the lowest point of the basin to facilitate gravity-driven flow. Inadequate slope and poorly positioned drains contribute to prolonged drying times and increase the risk of bacterial proliferation within the fixture.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

-

Drain Size and Capacity

The diameter of the drain opening and the capacity of the drainpipe must be appropriately sized to handle the anticipated volume of water discharged. A drain that is too small can create a bottleneck, causing water to back up and potentially overflow. In commercial settings where large volumes of water are frequently discharged, oversized drains and drainpipes may be necessary to ensure rapid and efficient removal. This consideration is crucial for preventing disruptions to workflow and maintaining sanitary conditions.

-

Drain Strainers and Debris Management

The inclusion of drain strainers is essential for preventing solid debris, such as mop strands, paint particles, or other foreign materials, from entering the drainpipe. Accumulated debris can cause blockages, reducing drainage efficiency and potentially leading to costly plumbing repairs. Regular cleaning and maintenance of drain strainers are necessary to ensure their continued effectiveness in preventing clogs and maintaining optimal drainage performance.

-

Material Composition and Corrosion Resistance

The materials used in the construction of the drain components, including the strainer, drainpipe, and associated fittings, must be resistant to corrosion and degradation from exposure to water, cleaning chemicals, and other substances commonly encountered in utility applications. Corrosion can weaken the drain components, leading to leaks, blockages, and reduced drainage efficiency. Stainless steel and durable plastics are often preferred for their corrosion resistance and longevity.

In summary, drainage efficiency is a multifactorial consideration, encompassing basin slope, drain size, debris management, and material composition. An effective drainage system not only promotes hygiene and prevents potential hazards but also contributes to the overall longevity and usability of the fixture, ensuring its continued performance in demanding environments.

4. Installation Location

The selection of a suitable installation location profoundly impacts the functionality and longevity of a plumbing fixture designed for utility purposes. This consideration transcends mere convenience; it dictates the efficiency of operation, accessibility for maintenance, and adherence to safety and sanitation standards. The chosen location influences the fixture’s exposure to environmental factors, the ease of connecting to existing plumbing infrastructure, and the potential for interference with other activities within the space. Consequently, a poorly chosen location can negate the benefits of even the highest-quality fixture.

For example, placing a fixture in an area with limited floor drainage can lead to persistent dampness and increased risk of slip hazards. Similarly, locating a fixture far from existing plumbing lines can necessitate extensive and costly modifications to the plumbing system. In commercial kitchens, placement must comply with health codes, ensuring sufficient separation from food preparation areas to prevent cross-contamination. A practical illustration is the installation of a fixture near a loading dock in a manufacturing facility, providing convenient access for cleaning equipment and minimizing disruption to production processes. Conversely, situating the same fixture in a dimly lit, poorly ventilated corner of the facility would hinder its usability and increase the likelihood of neglect, leading to unsanitary conditions and potential equipment malfunction.

In summary, the installation location represents a critical determinant of a fixture’s overall effectiveness. Careful assessment of spatial constraints, accessibility requirements, plumbing infrastructure, and regulatory compliance is essential. A strategic approach to placement maximizes the fixture’s utility, minimizes maintenance burdens, and contributes to a safer and more efficient working environment. The challenge lies in balancing these competing factors to achieve an optimal outcome, ensuring the fixture serves its intended purpose effectively and contributes to the overall operational goals of the facility.

5. Code Compliance

Adherence to relevant building codes and plumbing regulations is a non-negotiable aspect of utility fixture installation. These codes are designed to ensure public health and safety, prevent contamination of potable water supplies, and promote responsible waste management. Failure to comply with applicable codes can result in significant penalties, including fines, mandatory rework, and potential legal liability. Consequently, a thorough understanding of local, regional, and national code requirements is essential for all stakeholders involved in the design, installation, and maintenance of these fixtures. Compliance considerations include backflow prevention, proper drain connections, accessibility standards, and appropriate materials selection, each contributing to the overall safety and functionality of the plumbing system.

A primary example of code compliance in practice involves backflow prevention. Regulations typically mandate the installation of backflow preventers on water supply lines connected to fixtures to safeguard against the reverse flow of contaminated water into the potable water system. This is particularly critical in environments where the fixture is used for handling hazardous materials. Another example concerns drain connections. Codes often specify the type and size of drainpipes required to ensure proper drainage and prevent sewer backups. In commercial settings, grease interceptors may be required to prevent the discharge of fats, oils, and grease into the municipal sewer system, mitigating the risk of sewer blockages and environmental damage. Accessibility standards, such as those outlined in the Americans with Disabilities Act (ADA), also mandate specific dimensions and clearances to ensure individuals with disabilities can safely and independently use the fixture.

In conclusion, code compliance is not merely a procedural formality but an integral element of responsible plumbing practice. It safeguards public health, protects water resources, and promotes the long-term reliability of plumbing systems. While navigating the complexities of building and plumbing codes can present challenges, particularly given regional variations, adherence to these standards is paramount. Ignoring code requirements exposes stakeholders to legal and financial risks, undermines the integrity of the plumbing system, and jeopardizes the health and safety of building occupants.

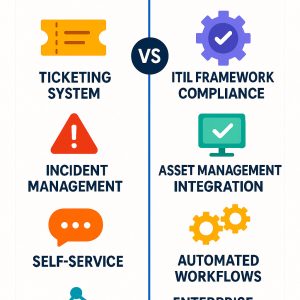

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

Frequently Asked Questions

The following questions and answers address common inquiries and concerns regarding the selection, installation, and maintenance of utility plumbing fixtures. These responses aim to provide clear and concise information for informed decision-making.

Question 1: What constitutes a service sink?

A specialized plumbing fixture designed for tasks involving dirty water disposal and cleaning, typically found in utility rooms, garages, or commercial settings. It is often deeper and more durable than standard sinks.

Question 2: What are the primary differences between a service sink and a standard sink?

The primary differences lie in depth, material, and intended use. Service sinks are typically deeper, constructed from more durable materials (e.g., stainless steel or heavy-duty polypropylene), and designed for handling dirty water and harsh chemicals, unlike standard sinks designed for personal hygiene or food preparation.

Question 3: What materials are commonly used in the construction of service sinks, and what are their respective advantages?

Common materials include stainless steel, polypropylene, and cast iron. Stainless steel offers exceptional durability and resistance to corrosion. Polypropylene provides chemical resistance and is lightweight. Cast iron offers robustness and stability but may be susceptible to corrosion if not properly maintained.

Question 4: What factors should be considered when determining the appropriate capacity for a service sink?

Factors to consider include the frequency of use, the volume of materials to be processed, the size of items to be cleaned, and any regulations regarding the disposal of hazardous materials. Adequate capacity prevents spills and ensures efficient cleaning processes.

Suggested read: Ultimate Guide to Service Marks: Protecting Your Brand Identity

Question 5: What are the key considerations for ensuring adequate drainage efficiency in a service sink installation?

Key considerations include the slope of the basin floor, the placement and size of the drain, the use of drain strainers to prevent clogs, and the material composition of the drain components to ensure corrosion resistance. Efficient drainage prevents standing water and promotes hygiene.

Question 6: What are the essential code compliance requirements that must be addressed during the installation of a service sink?

Essential code compliance requirements include backflow prevention, proper drain connections, accessibility standards (e.g., ADA compliance), and adherence to local plumbing regulations. These requirements ensure water safety, proper waste management, and accessibility for all users.

These FAQs highlight critical aspects of service sink selection, installation, and maintenance, underscoring the importance of informed decision-making to ensure optimal performance and regulatory compliance.

The subsequent section will address advanced topics, including specialized applications and troubleshooting common issues.

Service Sink Considerations

The following tips offer guidance on maximizing the functionality and lifespan of a utility fixture, emphasizing proactive measures and informed decision-making.

Tip 1: Select Material Based on Intended Use. The composition of the fixture should align with the anticipated exposure to chemicals, abrasives, and physical stress. Stainless steel is recommended for corrosive environments, while reinforced polypropylene suits lighter-duty applications.

Tip 2: Implement a Regular Cleaning Schedule. Routine cleaning prevents the buildup of grime and debris, mitigating bacterial growth and preserving the fixture’s aesthetic appeal. Utilize appropriate cleaning agents compatible with the fixture’s material to avoid damage.

Tip 3: Ensure Proper Drain Strainer Maintenance. Regularly inspect and clean the drain strainer to prevent clogs and maintain efficient drainage. Replacement of damaged or worn strainers is critical to prevent debris from entering the drainpipe.

Tip 4: Protect Against Physical Damage. Exercise caution when handling heavy or sharp objects near the fixture to prevent dents, scratches, or cracks. Implement protective measures, such as rubber mats or bumper guards, in high-traffic areas.

Tip 5: Inspect Plumbing Connections Periodically. Regularly examine water supply and drain connections for leaks or signs of corrosion. Address any issues promptly to prevent water damage and maintain the integrity of the plumbing system.

Suggested read: The Essential Guide to Finding a Top-Notch Service Professor

Tip 6: Comply with Backflow Prevention Requirements. Ensure that backflow prevention devices are properly installed and maintained in accordance with local plumbing codes. This prevents the contamination of potable water supplies and ensures regulatory compliance.

Tip 7: Choose an Accessible Location. When installing or replacing the fixture, select a location that offers convenient access for intended users and facilitates cleaning and maintenance activities. Adherence to accessibility standards is paramount.

Adherence to these tips promotes operational efficiency, extends the lifespan of the fixture, and ensures compliance with relevant health and safety standards.

The next section provides a comprehensive conclusion, summarizing the key takeaways from this discussion and reinforcing the significance of proper utility fixture management.

Conclusion

The preceding discourse has thoroughly examined the specialized plumbing fixture, delineating its essential characteristics, operational considerations, and regulatory requirements. A comprehensive understanding of material selection, capacity determination, drainage efficiency, installation location, and code compliance are fundamental to ensuring optimal performance and longevity. Furthermore, adherence to best practices, including regular maintenance and proactive damage prevention, contributes significantly to the sustained utility of this fixture.

Given the critical role it plays in maintaining sanitation, managing waste, and facilitating a range of industrial and domestic activities, the responsible selection, installation, and upkeep of the service sink warrants diligent attention. Failure to do so carries tangible risks, from compromised hygiene and operational inefficiencies to potential regulatory violations and environmental harm. Therefore, stakeholders are encouraged to leverage the information presented herein to inform their decisions and promote the responsible management of this essential plumbing component.