How to Properly Recharge Your AC System. Hey guys here and today, I’m going to show you how to properly recharge your air conditioning system. Many people are afraid to do work on their ac system, but this video will take those fears away and it’ll. Show you how easy it really is to recharge your air conditioning system. The hardest part of ac work is having the correct tools.

So I’ll put links to all these tools in the description here. Are the tools you’re going to need to do a proper ac system? Recharge we have a set of manifold gauges which tell you the pressure of the air conditioning system, which is very important. We also pull a vacuum on the ac system and fill up the ac system through this.

So you need to have a set of manifold gauges. Then you’re going to need a vacuum pump because we’re going to have to pull a vacuum on the ac system. We’re going to need refrigerant, I’ll, explain how much and what kind in a second and then you’re going to need a nozzle to tap the refrigerant.

In some cases you might need a digital scale to measure how much refrigerant you’re putting in and then any time you’re working on the air conditioning system make sure you use gloves and safety glasses, because if any refrigerant leaks out, you don’t want to cause frostbite. And you don’t want it to blind you with these tools here you could do a proper ac system recharge since you’re going to go out and buy refrigerant. You need to know how much refrigerant and what kind of refrigerant to purchase and to figure that out. There’s a sticker located on your car.

Suggested read: Martin Luther King Jr Multi Service Ambulatory Care Center: Your Gateway to Accessible Healthcare in South Los Angeles

You can actually see it’s right here. Usually the sticker is found right in the front on this piece of metal right here or the plastic trim that covers the metal. The other place you could find it is up on the hood somewhere.

You can see, there’s two stickers there and there, but in this case we have it right here and you can see on this sticker. It says we’re using hfc134a, which is the same thing as r134a, which is the most common in today’s cars. It’s better for the environment than the old, refrigerant and it’ll.

Also tell you how much you’re going to have to add – and you can see here it says we’re going to have to add anywhere between 126 pounds and 139 pounds of refrigerant. So if you convert that from pounds of ounces, there’s 16 ounces in a pound, that means we’re going to need about 22 ounces of refrigerant. Now most of the refrigerant that I found in the store came in 12 ounces. So that means we’re going to have to get two cans, which is 24 ounces and because we need 22, not 24 ounces.

That’s why we’re going to be using a scale to make sure we only use 22 ounces not to hold 24. The other thing is, you can see here we have r134a, which is what we need and then finally, the last thing is this refrigerant does not have any additives. There’s no oil, there’s no leak, stopping additives.

There’s none of that. You want straight refrigerant. So that’s how you find what refrigerant you’re going to need so to charge the air conditioning system you’re, going to be doing two main things.

The first thing is going to be pulling a vacuum on the whole ac system. This draws out any air and moisture. That’s in the ac lines, the evaporator, the condenser and the compressor moisture will destroy ac systems.

So this is a very, very important step if you skip this step, you’re pretty much wasting your time since the moisture is just going to cause a leak in the future and the second step is going to be to recharge your system with refrigerant, pretty simple. So, let’s begin so. The first thing to do is connect our manifold gauge to the ac system.

You want to make sure that all these valves are in the closed position. This side right here, is the low pressure side of the gauge. This right here is the high pressure side of the gauge and the middle is where you’re going to pull a vacuum and then add the refrigerant. In later on.

I want you to note that the low pressure connector only fits on the low pressure side and the high pressure connector only fits on the high pressure side, they’re, two different sizes, so you can’t mix them up. You can see here, here’s the low pressure side and then we look over here right down in here. This is the high pressure size. It even has an h on it and if we take our low pressure hose and we try to connect it, it just doesn’t fit at all same thing.

Suggested read: Understanding the Department of the Treasury Bureau of the Fiscal Service: Your Complete Resource for Federal Financial Operations

If we take our high pressure hose, it’s just way too big and does not fit on it. So you don’t have to worry about mixing those up to connect these adapters. You just push down and slide it over and let go and we’re going to connect our low pressure, which is this blue line to our low pressure port right here.

Make sure it’s in there good get our high pressure line here, which is the red and we’re going to connect it right down here to our high pressure line good now back at our gauges again, these are closed off we’re just going to come over here and We’re going to open these up open the low pressure side, good and open the high pressure side with the high and low pressure side opened up.

We come over here. You can see here at the low side it’s at 0 psi, which is exactly what we want, and you look here at the high sides at 0 psi, which is exactly what we want, so there’s no pressure in the system. Obviously, we know that, because we replaced the compressor now, we can start pulling a vacuum all right.

The last line we have to connect is this yellow line which is going to go to our vacuum pump and I’m just going to move this down because my vacuum pump’s going to be on the ground you can see. My vacuum pump is right here. Take off that connect our line, you don’t need to tighten these more than hand tight, don’t get a pliers or something and really crank these down.

There’s gaskets in here that’ll do the job, for you so just hand, tighten all the connections good if there’s any refrigerant. In your system make sure you go to a garage and get the system professionally evacuated, so you don’t let this gas out into the atmosphere. This refrigerant is pretty nasty stuff, so be environmentally responsible. So now that we have everything connected, these are still in the off position.

We have our low pressure line connected securely, that’s opened up, we have our high pressure line connected securely, that’s opened up and then now we have our yellow vacuum line connected securely. Let’s go turn on the vacuum pump. Okay, so I’m going to go turn on the pump.

We can see here. Nothing has happened yet. I’m going to open up both of these valves and you’re going to hear the pump work and you’re also going to see this get sucked down.

So I’m just going to be focusing right here, because this has the vacuum on the gauge, even though this goes below zero. It doesn’t have the actual readings and you can see we’re almost at 30 inches of mercury for vacuum, which is exactly where we want to be so after letting this run for a few minutes, there’s just about 30 inches of mercury of vacuum. I’m going to close these and I’m going to close our vacuum pump. Now I’m going to let this sit for about an hour and what we want to see is we want to see this stay at 30 inches of mercury.

If this stays at 30 and doesn’t leak at all, then that means our system is completely sealed, which is exactly what we want. We want a completely sealed system, so I’ll come back in about an hour and we’ll see if this moved okay, one hour later – and this looks pretty much identical – it looks like nothing at all leaked out. This is great means. Our job was done correctly and we have no ac system leaks anymore.

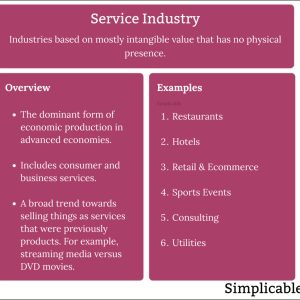

Suggested read: Comprehensive Guide to the Service Industry Definition

Now that we know there’s no leaks, we want to continue to pull a vacuum for 45 minutes, so I’m going to go and turn the vacuum back on and I’m going to open up both of these valves again good and now we’re sucking vacuum for 45 minutes. This is going to evacuate all the moisture and air out of the system, so it’s nice and dry in there. So now is a good time to go run. Some errands go, do something and let the pump do its job all right.

It’s been 45 minutes and everything is looking really good here. So what we’re going to do is we’re going to close off our lines here. So there’s no more vacuum.

Now we’re going to go over here and shut off the pump. The next thing we do is add the refrigerant, if you replace the major component in the ac system, such as the air conditioning compressor, the condenser or the evaporator you’re going to have to add oil to your system. Again, we can look at this sticker right here.

It’ll tell you the type of oil that you need, consult your service manual on how much oil you’re going to need to use. In my case, when I replace the compressor, it came preoiled with the correct oil and the correct amount of oil. So I didn’t have to do anything which is really convenient.

If you end up having to add oil, what you could do is you could add it through your yellow line here, and you literally just take your line and you fill it with the correct amount of oil. And then you take this line and you connect your refrigerant bottle and then that’ll get drawn in to the ac system. The oil basically lubricates the whole system, but more specifically, it lubricates the compressor, so it doesn’t run dry.

Another thing that you should add right now is some uv dye. You add a little bit right to this line, make sure it’s ac system, uv dye, it’s only a few bucks totally worth it, because if you have any future leaks, then you’ll know where it’s coming from just like. You saw in my leak detection video since I already added the uv die when I did the leak detection, video it’s in there.

We don’t have to do that. So in this case I don’t have to add oil. It’s already preoiled and I don’t have to add uv dye. I already have it in there so now we’re going to go, connect our refrigerant to this line.

So the first thing we’ll do is connect our adapter right to the refrigerant can make sure it’s a nice tight seal. Now we’re going to connect our refrigerant can to our yellow line. Okay good! So now we’re going to screw down the adapter, which will pierce the can and with this screwed down. This is in the closed position.

Suggested read: Instant, Accurate Service Quotes - Get Your Project Started Today!

So no refrigerant is going to come out. Also remember that the manifold gauges are in the closed position and holding vacuum. So now we’re going to open up our can so we can purge the system so with this can in the open position, there’s some refrigerant in this line, but there’s also air in this line.

So, let’s purge it out what you do to purge the line of air. Is you get a screwdriver? You go to this purge tip right here and you just press down until the refrigerant comes out, and now we purge the system of any air. So let’s go start the truck all right. Let’s go starter up.

We want to make sure that the ac is on so we’re going to turn the fan on to low ac has to be on. You want to make sure the ac is on, because that means that the compressor will kick on when there’s enough pressure and that’s what’s going to draw in the rest of our refrigerant just so, we can see the temperature I’m going to put this thermometer right up In here you can see right now, it’s almost 90 degrees, so with our ac on and our fan on, let’s go add the refrigerant next open up the valve on the low pressure side of the manifold gauge.

Now refrigerant is flowing into the system. I’m going to put this down on a cool part of the engine compartment, but you don’t want to put this down on anything hot because it could heat up the can and cause an explosion which would not be good.

Now we just wait for the compressor to kick on perfect. It just kicked on and you can see the low pressure side dropped down to about 10 psi, while the high pressure side is slowly building pressure at around 100 psi, this will increase, as we add more refrigerant. If we check the compressor, you can see it’s clicked on, which is good.

Now we just wait for the compressor to suck out the refrigerant from the can, when you think the can is empty turn it over and give it a shake. You can look at the watch glass to see if any refrigerant comes out. You can see, there’s still some refrigerant left, so let’s wait a minute or two and then check it again.

A minute later, I’m pretty sure this is empty. Yep, it’s empty! So let’s take this off and put a new can on remember to close this valve here before you disconnect this. Can if you leave this valve open refrigerant’s, just going to come out of this yellow line. Now we could close this here all the way down, so it seals off this yellow hose twist the new can on and now we need to weigh it, because we only need 10 ounces out of the 12 that are in this can so get the can on The scale so it levels out and you can see the can – weighs 20 ounces exactly.

We want to add 10 more ounces to the system, since each can is 12 ounces, and we already added one can so far. I’m going to open up this can on the scale, and now we need to open up the manifold gauge on the low side to allow the refrigerant to get sucked in. I don’t want the refrigerant to spike and go all in at once, because it could turn to liquid and damage the compressor, so slowly add the refrigerant.

After a little, we could open up the valve the rest of the way to get the can down to 10 ounces, all right we’re almost at 10 ounces and I’m going to close this valve up.

Suggested read: User-Friendly Service Project Ideas for the Service-Minded

So you saw it go down to 10 ounces. That’s 22 total ounces and the system is completely and properly filled. Now, let’s remove the manifold gauge. Both the high and low pressure valves on the manifold gauge are closed.

Next, let’s shut off the high side valve and then pop that off and let’s shut off the low side valve and then pop that off make sure we screw our caps back on to protect the schrader valve and it also helps seal the system. Good and good. And we are done all right, so that’s how you charge an ac system.

Let’s go check out the temperature real, quick, look at that 42 to 43 degrees in there. That is beautiful! That’s exactly what we want way better than the 90 degrees that was coming out of there before when the compressor was bad, and that is how you properly recharge your air conditioning system. Hopefully this video was helpful if it was remember to give it a thumbs up.

Also, if you’re not subscribed, consider subscribing up on the screen are going to be a couple of howto videos related to the ac system. To get to those videos, you can click on the screen or find the links in the description below.